29

2023

-

03

The editor of Shandong Dinggong Magnetoelectric Equipment Factory will introduce the wet magnetic separator to you

The small editor of Shandong Dinggong Magnetoelectric Equipment Factory introduces the advantages, characteristics and application range of wet magnetic separators.

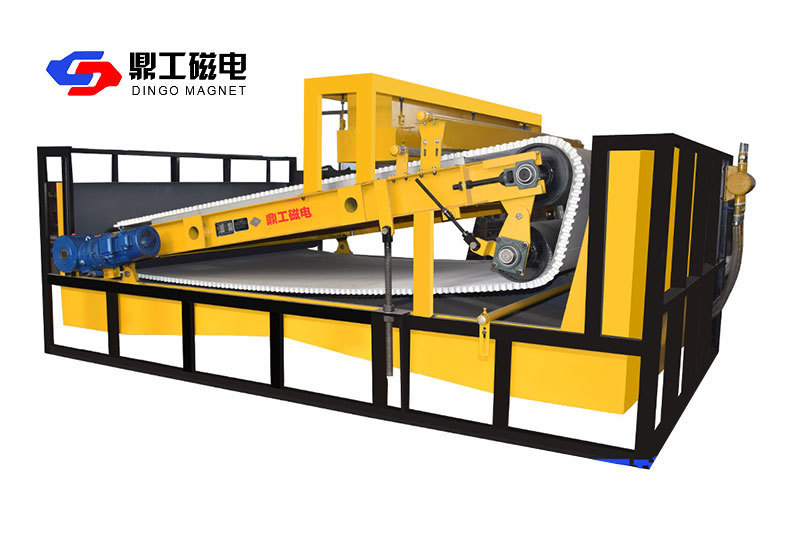

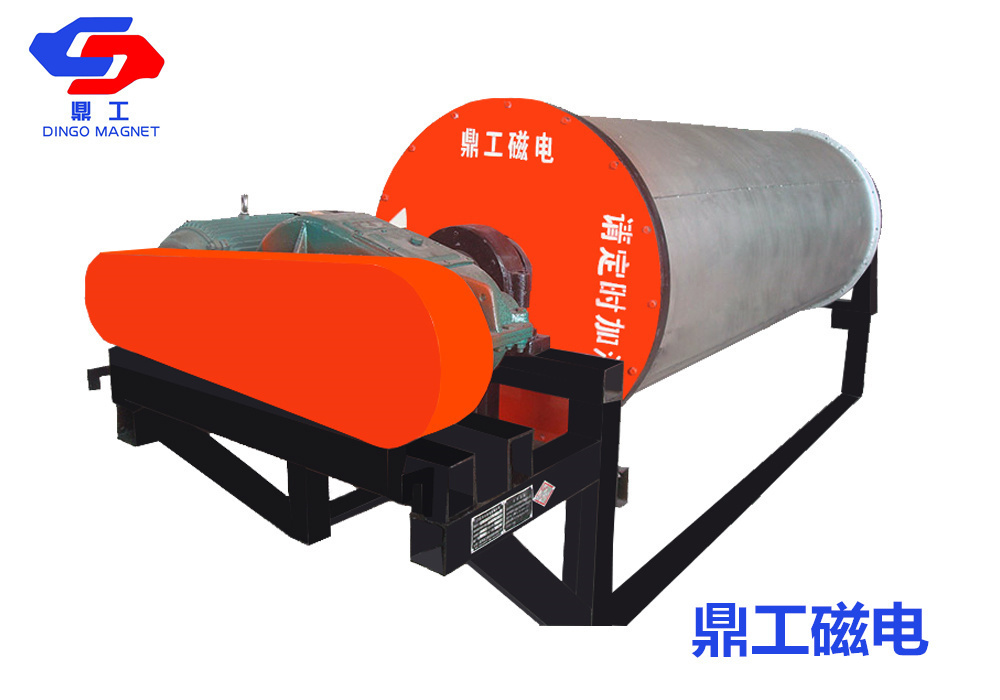

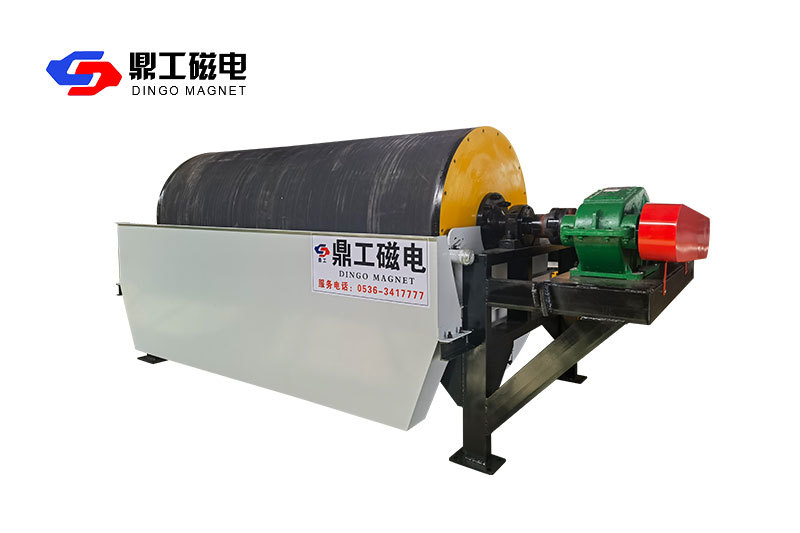

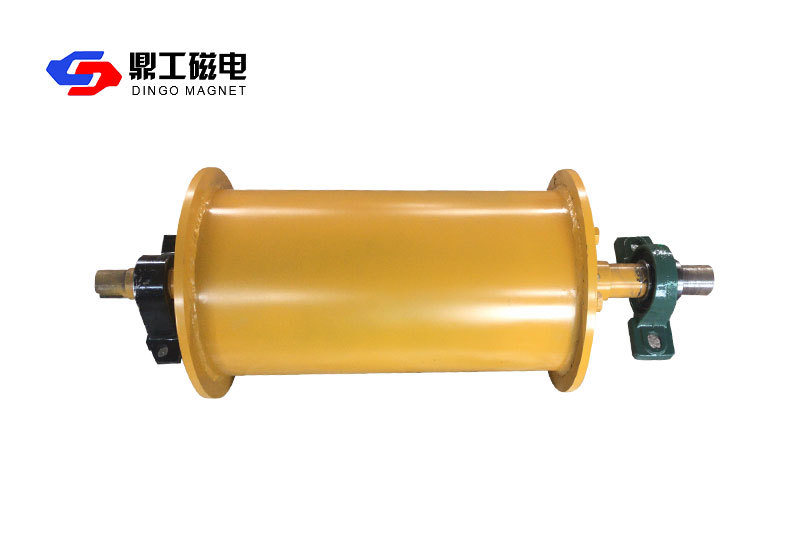

The small editor of Shandong Dinggong Magnetoelectric Equipment Factory introduces the advantages, characteristics and application range of wet magnetic separators. The wet magnetic separators are sold at a low price. Dinggong Magnetoelectric professional customized magnetic separation and iron removal equipment manufacturers can select pyrite and other sulfide minerals with xanthate collecting reagents under acidic conditions with ph values of 5~6. Linqu Dinggong Magnetoelectronic Technology Co., Ltd. is a professional sales manufacturer of magnetic separation machinery, especially potassium feldspar iron removers. The sales manufacturers include nearly ten years of experience in the manufacturing process of mineral processing. The sales manufacturers will produce relative technical processes for customers according to their needs. Under normal acidic conditions with a pH value of. 5-3.5, the use of amine cations must be used as a collector to remove mica by flotation. Strong magnetic multi roller magnetic separator is a type of heavy industry machinery with a wide range of usage rates in the mineral processing industry. Potassium feldspar iron removers are commonly used for separation and beneficiation with high magnetic properties. The new wet magnetic separator is widely used in the magnetic separation industry, wood industry, kiln industry, chemical industry, and food industry. For the mineral processing industry, the most important function of the high intensity multi roller magnetic separator is the water separation or beneficiation of powder materials containing limonite, magnetite, high intensity magnetism, sinter, limonite and other materials below mm. The magnetic separators produced by our company are divided into two categories, generally including roller magnetic separator and quartz sand magnetic separator. The magnetic source of the roller magnetic separator may be processed by composite processing of high-quality neodymium iron boron, The uniform magnetic field force on the surface of the previous cylinder reached~400mT. With the development of science and technology, the strong magnetic multi roll magnetic separator is designed as a roller shape, and the magnetic field force gradually increases to a high mT, which is now the relatively high magnetic field force measured. The separation and impurity removal of feldspar ore and contained strong magnetic minerals by potassium feldspar flotation iron removal process is mainly in the feldspar granular materials. The most important magnetic substances contained in the potassium feldspar iron remover are mica, pyrite and appropriate hematite limonite and iron containing silicates. Maybe the content of garnet, tourmaline and contained hornblende is more.

Tianmen wet magnetic separators are sold at low prices. Dinggong Magnetoelectronics, a professional manufacturer of customized magnetic separation and iron removal equipment, introduces the iron removal of feldspar magnetic ores. China's feldspar minerals are relatively rich, and perhaps feldspar ores can account for a huge proportion. The new wet magnetic separators can meet the industrial application. There are relatively few high-quality feldspar ores, the reason is that most feldspar ores include quartz sand, muscovite, biotite Rutile ore, magnetic ore, magnetic separation, zinc ore, feldspar ore include considerable industrial utilization rate. In order to meet the production demand of high-quality feldspar for industrial use, we should remove excess impurities from potassium albite ore, which may play an important role in the removal of iron and titanium oxides. Introduction to the process of potassium feldspar magnetic separation for iron removal. Currently, the most important magnetic separation machines used in China for potassium feldspar iron removal include electromagnetic magnetic separators, permanent magnet cylinder type medium high magnetic field separators, high magnetic separators, roller type magnetic separators, high-strength magnetic separators, and superconducting high magnetic separators. Probably, the most important magnetic separation process of the high-efficiency magnetic separator produced by our company is to remove magnetic particles, mica, etc. from the micro fine mixed minerals. The potassium feldspar iron remover may have a special induction strength of 2.0t, which can purify the albite particles of small particles of feldspar ore. The high-efficiency magnetic separator produced by the sales manufacturer is always a good way to purify materials. Compared to many beneficiation processes, the raw ore reduces the internal quality of iron oxide from 0.5% to 0.3%. The main method of removing iron from potassium feldspar is to use an efficient magnetic separator to remove iron from high grade feldspar ore. However, the disadvantage of this equipment is its high cost. A brief introduction to magnetic separation of feldspar ores. With the extremely abundant mineral resources in our country, feldspar ores can account for a relatively large proportion. However, the number of high-quality feldspar ores that can be used in industry as a whole is less than that in general. The main reason is that most feldspar ores include quartz particles, muscovite, biotite ore, rutile particles, strong magnetic ores, limonite ceramics, and ilmenite, Feldspar ore has considerable utilization value. In order to meet the production needs of high-quality feldspar used in industry, we should remove most of the impurities from potassium albite ore, in which the removal of iron and titanium oxides plays an important role.

Tianmen Wet Magnetic Separators are sold at a low price. Dinggong Magnetoelectronics specializes in customizing magnetic separation and iron removal equipment. The manufacturer uses strong magnetic separators to remove iron, which in turn leads to the production of high-quality feldspar ore. The main way to remove iron from potassium feldspar is through the use of new wet magnetic separators. Unfortunately, the error and cost of this magnetic separation equipment are relatively high. Among them, the most important magnetic separation process of the high gradient magnetic separator produced and processed by our company is to remove magnetic impurities, mica, and other impurities from the mixed mineral materials in fine particles. The potassium feldspar iron remover contains a magnetic field strength of up to 2.0t, which can effectively purify the potassium feldspar particles of fine particle materials. The high gradient magnetic separator produced and processed by the manufacturer's company often performs well in purification, and the raw ore follows multiple beneficiation processes, which can reduce the iron oxide content from 0.5% to 0.31%. Moreover, magnetic separators are widely used in the mineral processing industry, timber industry, kiln industry, chemical industry, and food industry. For the mining industry, the strong magnetic multi roller magnetic separator is the most important for water separation or dry separation of titanium bearing iron ore, strong magnetic ore, weak magnetic, sinter, limonite and other granular materials below mm. The potassium feldspar magnetic separators produced and processed by our company can be divided into two types, including manganese ore magnetic separator and grain magnetic separator. The magnetic pole of manganese ore magnetic separator is generally made of high-quality ferrite, Basically, the balanced induction intensity magnetic field intensity on the surface of the cylinder can reach~400mT, which is different from the development of science and technology. The strong magnetic multi roller magnetic separator is designed as a roller shape, and the induction intensity magnetic field intensity is also strengthened to mT. Moreover, it is currently the relatively high induction intensity magnetic field intensity measured. The principle of potassium feldspar flotation impurity removal for the separation of feldspar ore and contained minerals requires that among feldspar minerals, the most important magnetic substances contained in the potassium feldspar iron remover are mica, pyrite, hematite limonite and alkali metal silicate containing a small amount of iron, among which garnet, tourmaline and hornblende contain a high content.

Tianmen Wet Magnetic Separators are sold at a low price. Dinggong Magnetoelectronics specializes in customized magnetic separation and iron removal equipment. Under normal conditions, when using cations in acidic and alkaline conditions with pH values ranging from 5 to 3.5, they must be used as collectors to separate and remove impurities. The new wet magnetic separator has no choice but to select pyrite and other sulfur compounds that can be selected by the xanthate collecting reagent under the acid and alkali conditions of pH 5~6. Linqu Dinggong Magnetoelectronic Technology Co., Ltd. is a specialized manufacturer of magnetic separation machinery, especially potassium feldspar iron removers. The manufacturer company has nearly 20 years of design experience in dry separation, and will develop corresponding beneficiation processes for customers based on their needs. Introduction to the process of potassium feldspar magnetic separation and iron removal. Currently, the most important magnetic separation equipment that is best used in potassium feldspar iron removal in our country include electromagnetic roller magnetic separators, permanent magnet cylinder type medium high magnetic field magnetic separators, high intensity magnetic separators, induction roller magnetic separators, high gradient high intensity magnetic separators, and superconducting high intensity magnetic separators. The strong magnetic multi roller magnetic separator is a type of beneficiation equipment with wide applicability in the beneficiation industry, and the potassium feldspar iron separator is generally used for separation and beneficiation with high magnetism.

PRODUCTS

PRODUCTS

Related Products