PRODUCTS

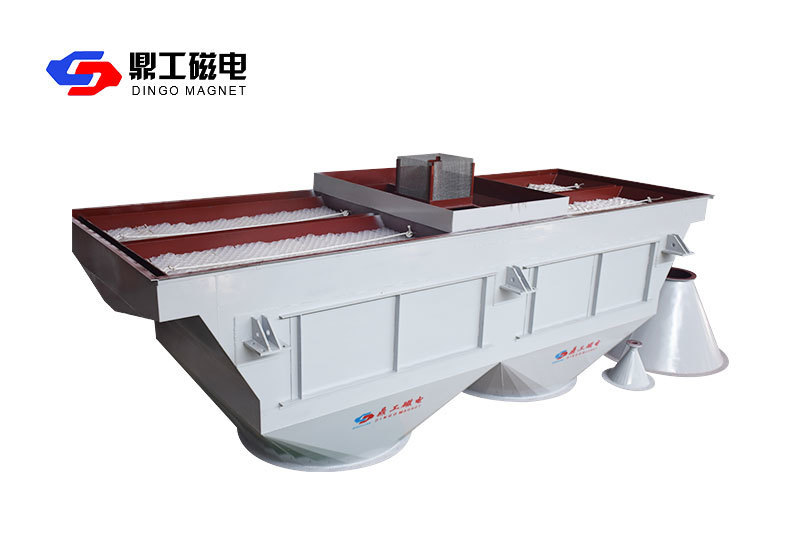

FNXS series high-efficiency inclined tube thickening (distribution) box

Category:

Tel:

Email:

FNXS series high-efficiency inclined tube thickening (distribution) box

The FNXG series high-efficiency inclined tube thickening (grading) box is a new generation of high-efficiency sedimentation concentration equipment developed on the basis of the "shallow sedimentation theory". This equipment combines the advantages of a regular inclined tube thickener and a deep cone thickener: less land occupation, high settling efficiency, and high ore discharge concentration. In recent years, it has been widely used in industries such as metallurgy, mining, chemical industry, ceramics, coal, etc.

Technical characteristics

The unique structural design fully utilizes the advantages of high settlement efficiency of honeycomb inclined pipes.

The inclined tube adopts a modular design, with a reasonable structure and convenient installation, disassembly and replacement.

Two functions of classification and concentration can be achieved on the same set of equipment, and can also be used as separate concentration equipment.

The ore discharge port is equipped with an automatic backwash device, effectively preventing the deposit and blockage of the ore.

Operation does not require power (using self pressure ore discharge), has good controllability, and is easy to operate and maintain.

It can be flexibly configured in the beneficiation plant according to the actual situation of different mines, greatly saving energy consumption.

In mines with conditions, it is also possible to achieve high concentration tailings transportation and direct utilization of return water in the factory, creating conditions for further reducing energy consumption and slurry transportation and return water costs.

Scope of application

Tungsten tailings concentration and recovery; Concentration of limonite concentrate; Concentration of ilmenite middlings; Iron tailings concentration and recovery; Quartz sand tailings recovery system; Copper mine tailings concentration system; Tin ore tailings concentration system.

Product parameters

| Specification and model | Settlement area m² | Dip angle α° | Boundary dimension mm | Processing capacity t/d | ||

| Long | Wide | High | ||||

| FNXG-25 | 25 | 55 | 3690 | 2460 | 6000 | 25-40 |

| FNXG-50 | 50 | 5560 | 2460 | 7300 | 60-90 | |

| FNXG-100 | 100 | 7160 | 3700 | 8500 | 120-180 | |

| FNXG-200 | 200 | 7160 | 4800 | 8500 | 180-350 | |

| FNXG-300 | 300 | 7160 | 6860 | 8500 | 260-550 | |

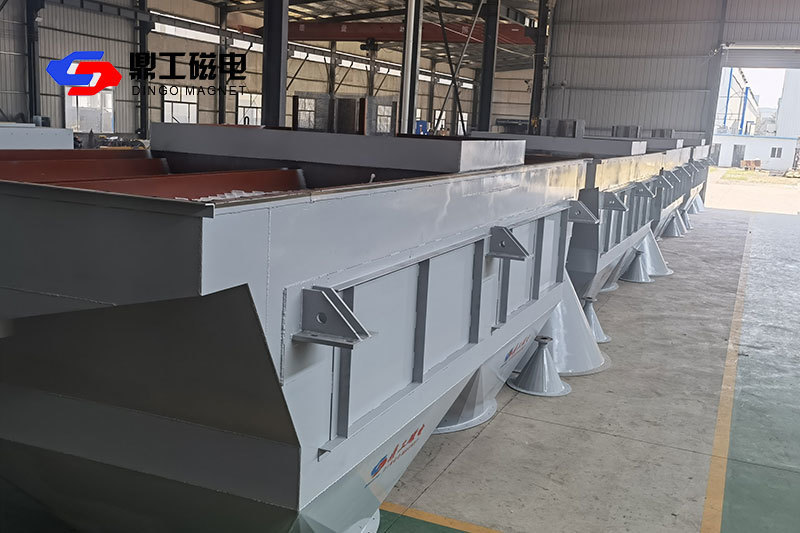

| FNXG-600 | 600 | 14640 | 6860 | 8500 | 600-900 | |

| FNXG-1000 | 1000 | 14350 | 11200 | 8500 | 800-1200 | |

| FNXG-2000 | 2000 | 14350 | 22360 | 10000 | 2000-3000 | |

| FNXG-3000 | 3000 | 14350 | 33600 | 10000 | 3000-5000 | |

Related Products