PRODUCTS

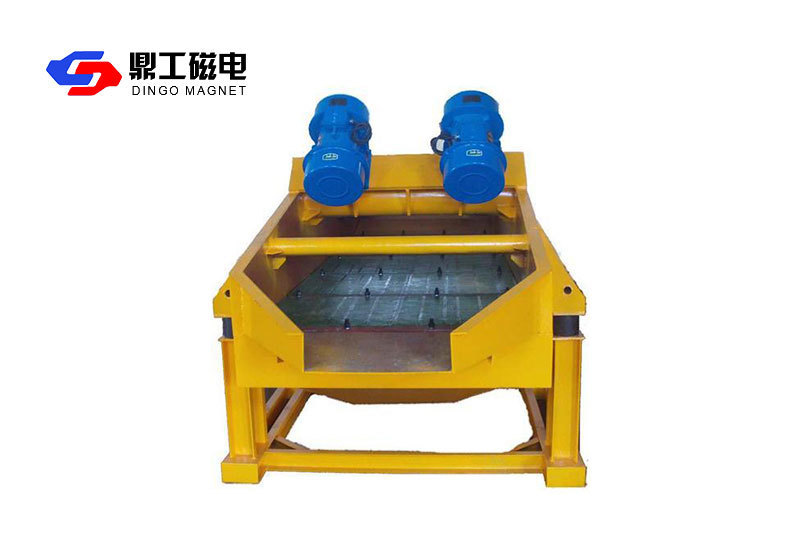

GT series high-frequency vibration dewatering screen

Category:

Tel:

Email:

GT series high-frequency vibration dewatering screen

The GT series high-frequency vibration dewatering screen is an efficient equipment for grading, dewatering, and mud removal. It is an ideal substitute for traditional tailings and concentrate processing equipment and processes such as tailings dams and thickeners. It is widely used for dehydration or tailings recovery in industries such as coal preparation, mineral processing, building materials, construction, power, and chemical engineering. The GT series dewatering screen is generally composed of components such as vibration source, screen box, vibration reduction device, screen mesh, frame, etc.

Technical characteristics

Using a vibration motor as the vibration source, the amplitude is adjustable, simple and reliable, and maintenance is convenient.

Equipped with a high wear-resistant and anti blocking polyurethane screen, with a high degree of modularization and easy replacement.

Adopting an innovative 45 degree standard oblique feeding area design and utilizing centrifugal force to assist in dehydration, the dehydration amount can be increased.

The tilt angle of the screen surface can be quickly adjusted to finely adjust the production process and achieve maximum output and efficiency.

The connection part is riveted with high-strength ring groove rivets specially used for vibrating screen, avoiding side plate cracking and other accidents caused by welding defect.

The use of low alloy structural steel plate (Q345C) ensures the overall stiffness of the equipment in cold areas of -40 ℃.

Working principle

The GT series high-frequency vibration dewatering screen consists of a pair of vibration motors with identical performance parameters as the excitation source. When two vibration motors operate in reverse at the same angular speed, the inertia force generated by their eccentric blocks is repeatedly superimposed or counteracted in a specific phase, resulting in a huge excitation force that drives the screen box to move periodically back and forth along a linear trajectory, causing the incoming material on the screen to gradually jump from the feeding end to the discharging end, During the jumping process, the part (water) smaller than the sieve hole falls through the sieve hole, while the rest is discharged from the discharge end, achieving the purpose of grading and dehydration.

Product parameters

| Model | Material Particle Size(mm) | Discharge moisture content(%) | Screen surface angle α(°) | Double amplitude(mm) | Power(kw) | Dry material processing capacity(t/h) | Overall dimensions(mm) |

| GT1036 | 0.15-1 | 15-30 | 0-5° | 2-4 | 2×5.5 | 20-35 | 3580×2185×2120 |

| GT1236 | 2-4 | 2×5.5 | 35-50 | 3580×2390×2120 | |||

| GT1536 | 2-4 | 2×7.5 | 40-85 | 3580×2700×2560 | |||

| GT1838 | 4-6 | 2×7.5 | 50-100 | 4250×3100×2882 | |||

| GT2138 | 4-6 | 2×7.5 | 70-130 | 4400×3360×2882 | |||

| GT2545 | 6-8 | 2×11 | 90-150 | 4500×3700×2930 | |||

| GT3060 | 6-8 | 2×11 | 120-200 | 6500×4365×3180 |

Related Products