PRODUCTS

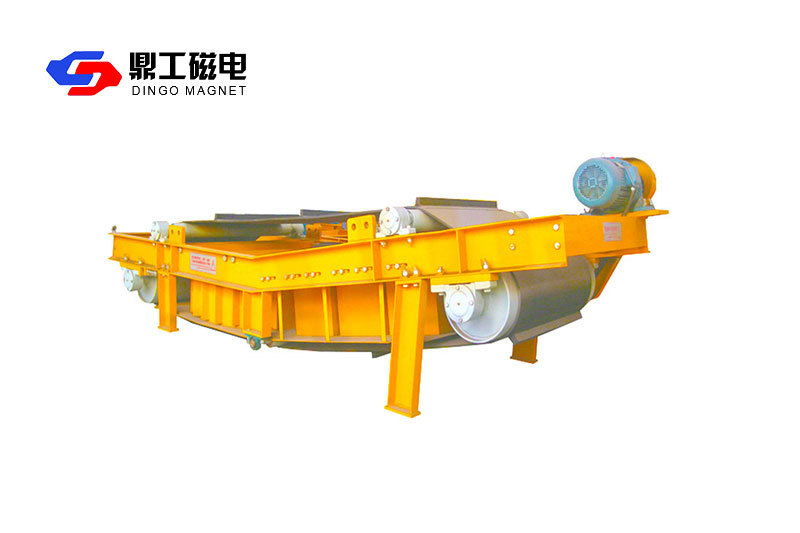

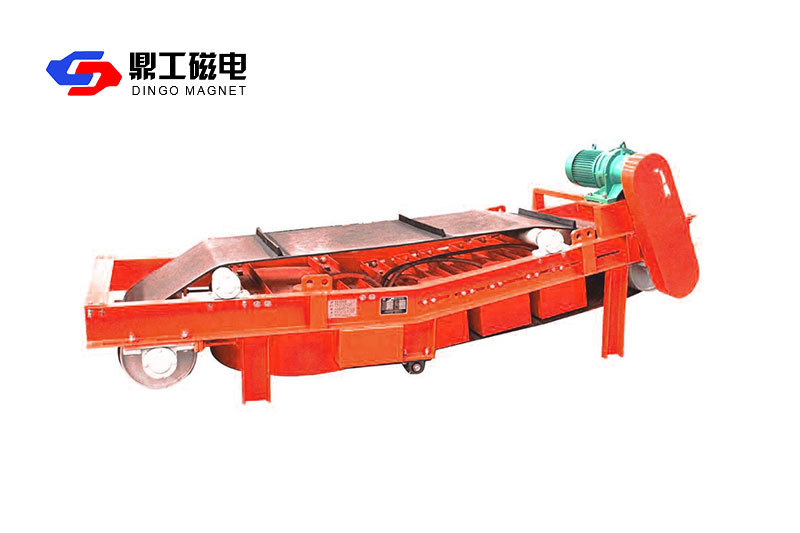

HTK magnetic ore iron removal system

Category:

Keywords:

Tel:

Email:

HTK magnetic ore iron removal system

Applicable scope

Suitable for iron removal on magnetic ore conveyor belts such as raw ore, sintered ore, pellet ore, and block ore. The HTK magnetic ore removal system relies on its unique magnetic circuit design to separate the selected material multiple times, thereby removing ferromagnetic impurities from the magnetic mineral material with the least amount of ore carried, achieving the goal of protecting subsequent crushing equipment.

Technical characteristics

1. The magnetic circuit adopts computer simulation design, with large magnetic penetration depth and strong magnetic force.

2. Cooperate with a metal detector to form an automatic detection and iron removal system, without iron leakage.

3. Intermittent excitation, low energy consumption, stable and reliable performance.

4. The sorting area adopts multi-level repeated magnetic separation to ensure a low amount of ore during iron removal.

5. Automatic iron unloading and simple maintenance. The drum adopts a drum structure and has automatic deviation correction function. The specially designed fully sealed bearing seat is suitable for occasions with high dust on site and can achieve long-term trouble-free operation.

6. The product has good compatibility, complete functions, manual and centralized control functions, and can meet various usage requirements.

Working principle

The HTK magnetic ore iron removal system is installed on the conveyor for transporting materials, with a metal detector installed at the front, a belt type electromagnetic iron remover installed on top of the belt conveyor, a non magnetic separation platform pulling the extracted iron parts behind the iron remover, and a rectifier control cabinet connecting the metal detector and the belt type iron remover. When the metal detector detects an iron signal, it sends the signal to the rectifier control cabinet. The control cabinet starts the belt type iron remover to unload the iron belt and excite it. At the main magnetic pole, the material with strong magnetic properties in the iron part is simultaneously sucked up, and it moves backwards through the rotation of the iron unloading belt. Due to the significant differences in shape and magnetism between magnetic ore and iron parts, after three rounds of sorting in the magnetic separation area, most of the magnetic minerals fall onto the conveyor belt, and a small amount of material is carried with the iron parts to the non magnetic separation platform for re separation. After four rounds of sorting, a good and low ore removal effect can be achieved.

Product parameters

| Project/Parameter/Model | Cooling method | Adaptive bandwidth mm | Average power ≤ kw | Main excitation power ≤ kw | Auxiliary excitation power ≤ kw | Unloading bandwidth mm | Drive power kw | Equipped with detector model | Weight kg | External dimensions mm | |||||

| A | B | C | D | E | F | ||||||||||

| HTK-6 | Free cooling | 650 | 2 | 5 | 4.8 | 500 | 3.0 | JYG-B-650 | 1450 | 3150 | 1050 | 980 | 1800 | 1700 | 858 |

| HTK-8 | 800 | 3 | 9 | 7.5 | 560 | 4.0 | JYG-B-800 | 2100 | 3500 | 1220 | 1180 | 2000 | 1600 | 998 | |

| HTK-10 | 1000 | 4.6 | 13 | 10.8 | 800 | 5.5 | JYG-B-1000 | 2920 | 3750 | 1380 | 1280 | 2100 | 1750 | 1196 | |

| HTK-12 | 1200 | 5 | 18 | 15 | 1000 | 5.5 | JYG-B-1200 | 3900 | 4240 | 1660 | 1370 | 2530 | 2165 | 1418 | |

| HTK-14 | 1400 | 6.5 | 25 | 18 | 1200 | 7.5 | JYG-B-1400 | 5150 | 4450 | 1750 | 1500 | 2800 | 2450 | 1520 | |

| HTK-16 | 1600 | 8 | 32 | 27 | 1400 | 11 | JYG-B-1600 | 5900 | 4650 | 2000 | 1600 | 3150 | 2600 | 1755 | |

| HTK-18 | 1800 | 9.5 | 45 | 36 | 1600 | 15 | JYG-B-1800 | 8700 | 4920 | 2180 | 1750 | 3450 | 2850 | 1950 | |

| HTK-20 | 2000 | 10.6 | 50 | 42 | 1800 | 15 | JYG-B-2000 | 11500 | 5100 | 2360 | 1800 | 3620 | 3200 | 2150 | |

Related Products