PRODUCTS

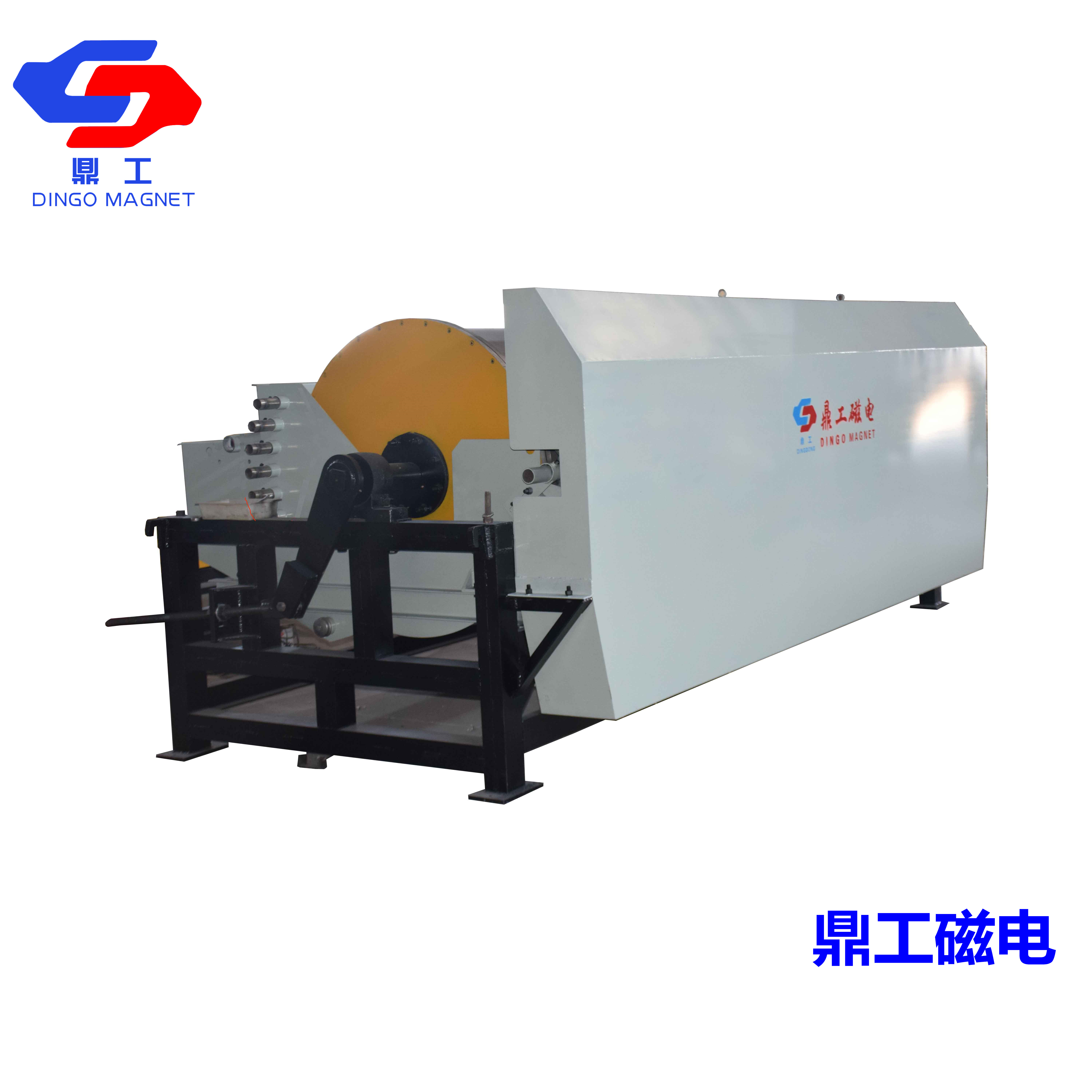

DJCT Precision Permanent Magnet Cylinder Magnetic Separator

DJCT permanent magnet drum magnetic separator is the latest type of magnetic separator in our company. It uses 240~270 degrees big envelope angle, multi-pole and magnetic pulsation structure combined with multi-channel rinsing water, top flushing device and new type of trough. It can increase the concentrate grade by 2~10 percentage points compared with conventional magnetic separator without reducing the recovery rate, thus solving the problem of magnetic cluster in conventional magnetic separator. It is difficult to improve the concentrate grade caused by packaged magazines.

Category:

Keywords:

Tel:

Email:

DJCT Precision Permanent Magnet Cylinder Magnetic Separator

DJCT permanent magnet drum magnetic separator is the latest type of magnetic separator in our company. It uses 240~270 degrees big envelope angle, multi-pole and magnetic pulsation structure combined with multi-channel rinsing water, top flushing device and new type of trough. It can increase the concentrate grade by 2~10 percentage points compared with conventional magnetic separator without reducing the recovery rate, thus solving the problem of magnetic cluster in conventional magnetic separator. It is difficult to improve the concentrate grade caused by packaged magazines.

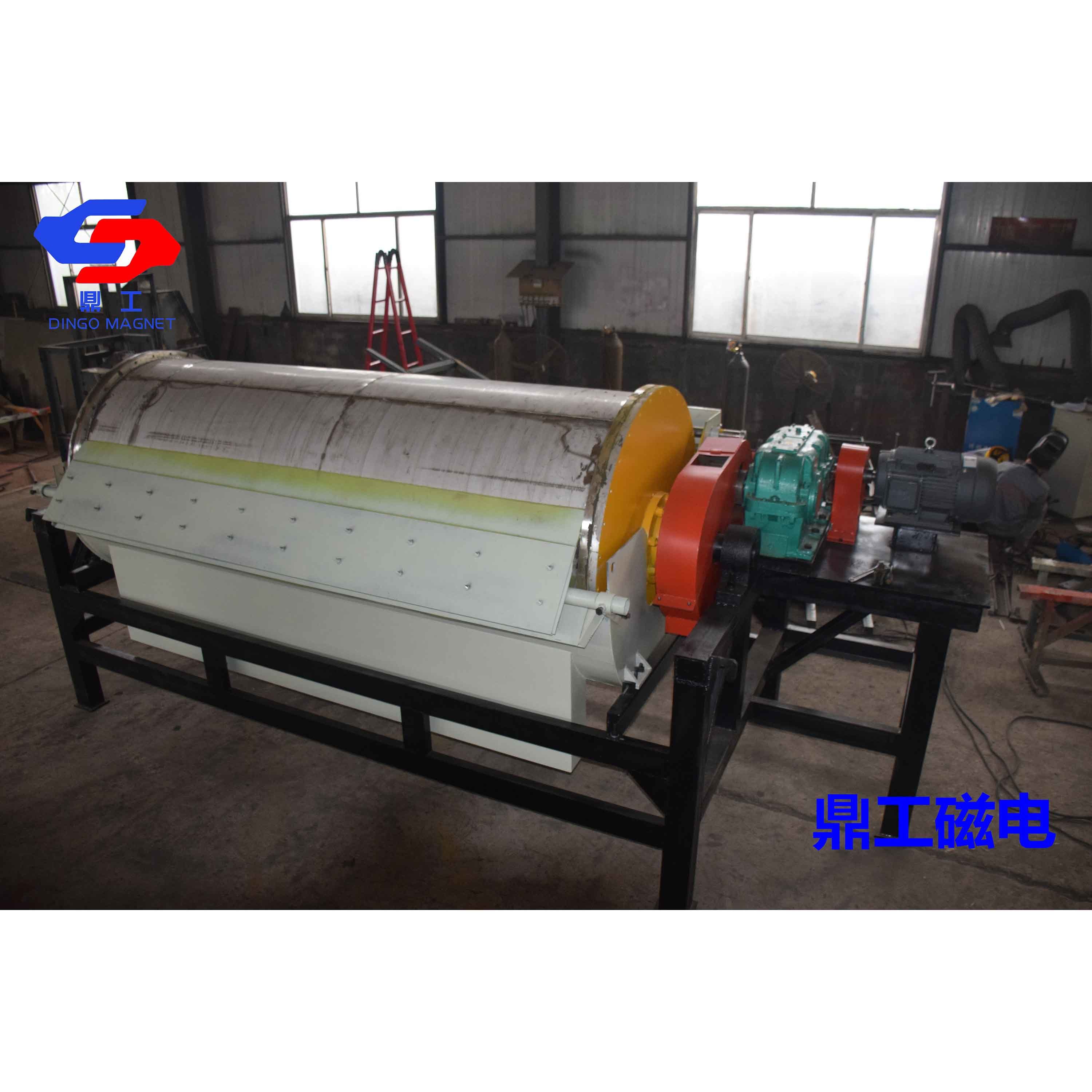

Scope of application:

This product is a wet magnetic separator designed for rinsing and purifying magnetic ores. According to technological requirements, magnetic ores are washed, purified, desliming and concentrating. Suitable for : separation and desliming of one stage grinding overflow products; mineral concentration before two stages grinding and filtration: desliming before magnetite entering fine screening and desliming before flotation; final separation of magnetite.

Working principle:

After the pulp is fed into the tubular feeding box, it is directly fed into the social security separation area through the slotted fabric. The magnetic minerals are first magnetized into chains, stratified, and then directly adsorbed on the surface of the separator by high-efficiency magnetic force. The magnetic concentrate is brought out of the liquid surface by the reverse rotating separator, and the magnetic concentrate is conveyed upward. In this process, the separation of water and mineral can be realized, and the concentration can be increased. At the same time, the silicon and sulfur in the concentrate can be washed by the washing water of the concentrate during the conveying process. Effective removal of impurities such as phosphorus and other impurities can improve the concentrate grade to the greatest extent possible. Finally,under the action of double scrapers, the concentrate is enriched in the concentrator to become a concentrate.The non-magnetic minerals in the concentrator are not affected by the magnetic force of the separator, and together with the ore flow, the tailings that enter the bottom of the separator are exported to become tailings or middlings.

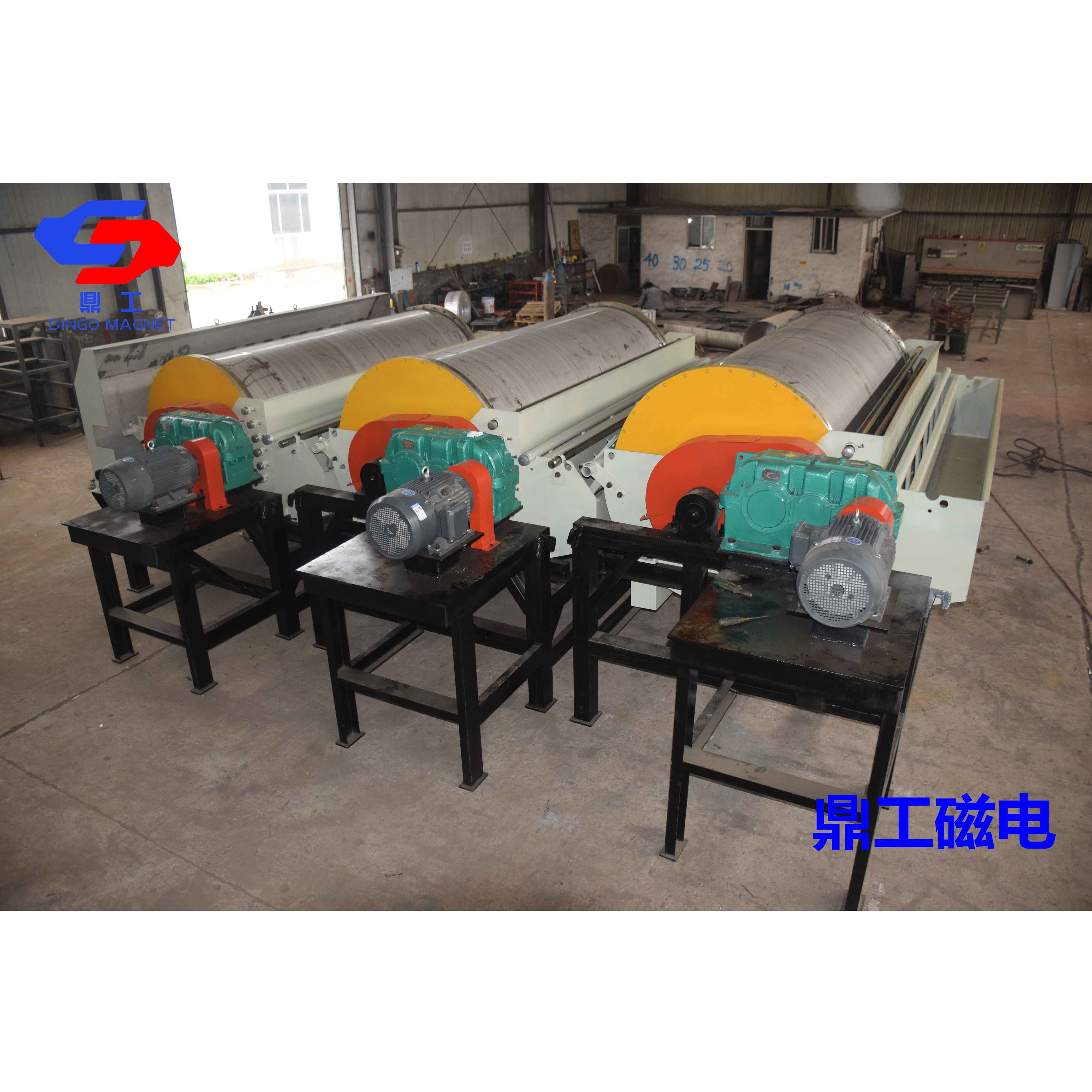

Product parameters:

|

Model

|

Cylinder size Cylinder Diameter * Cylinder Length)

mm

|

Maximum magnetic induction intensity

on cylinder surface

mT |

Processing capacity T/h |

Motor power kw |

Noise Db(A) |

Total weight of equipment kg |

| DJCT1024 | 1050×2400 |

Determine according to the nature of ore (100-600) |

25-50 | 11 | ≤75 |

5250 |

| DJCT1030 | 1050×3000 | 30-60 | 11 | 6700 | ||

| DJCT1224 | 1200×2400 | 40-70 | 15 | 7200 | ||

| DJCT1230 | 1200×3000 | 50-80 | 15 | 10000 | ||

| DJCT1236 | 1200×3600 | 60-90 | 22 | 14000 | ||

| DJCT1240 | 1200×4000 | 75-110 | 22 | 16000 | ||

| DJCT1245 | 1200×4500 | 85-120 | 22 | 19000 | ||

| DJCT1530 | 1500×3000 | 70-100 | 22 | 15500 | ||

| DJCT1540 | 1500×4000 | 90-130 | 30 | 19500 | ||

| DJCT1545 | 1500×4500 | 100-150 | 30 | 22000 | ||

| DJCT1550 | 1500×5000 | 120-160 | 30 | 24500 |

Related Products