29

2023

-

03

A professional manufacturer of magnetic separation and iron removal equipment for large-scale iron remover maintenance company Dinggong Magnetoelectronic Technology Co., Ltd

Dinggong Magnetoelectric Technology Co., Ltd., a professional manufacturer of magnetic separation and iron removal equipment, is a large-scale iron remover maintenance company.

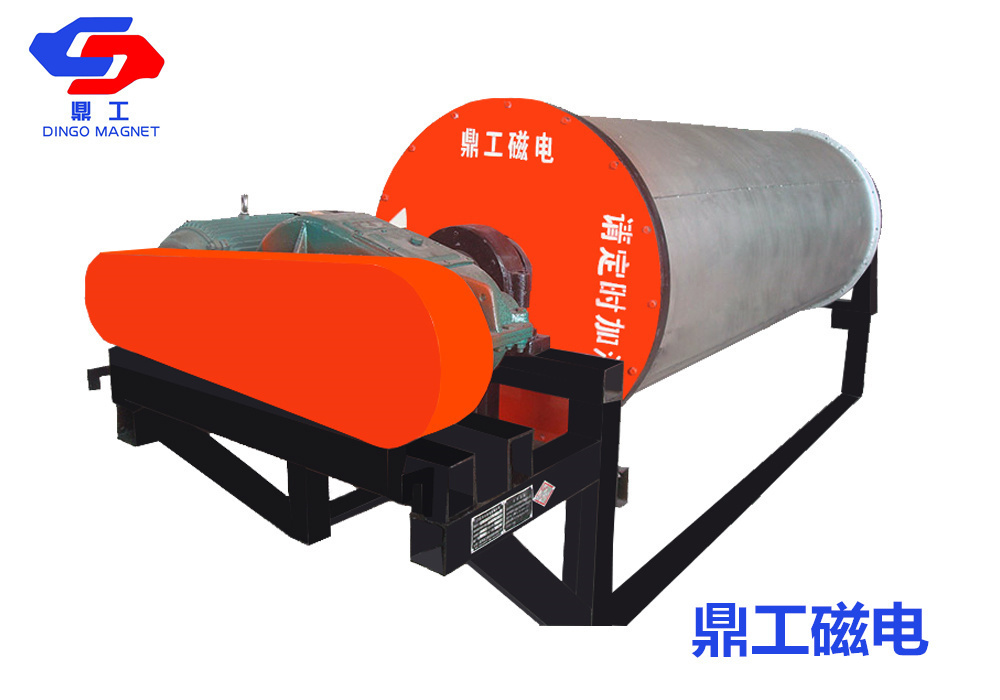

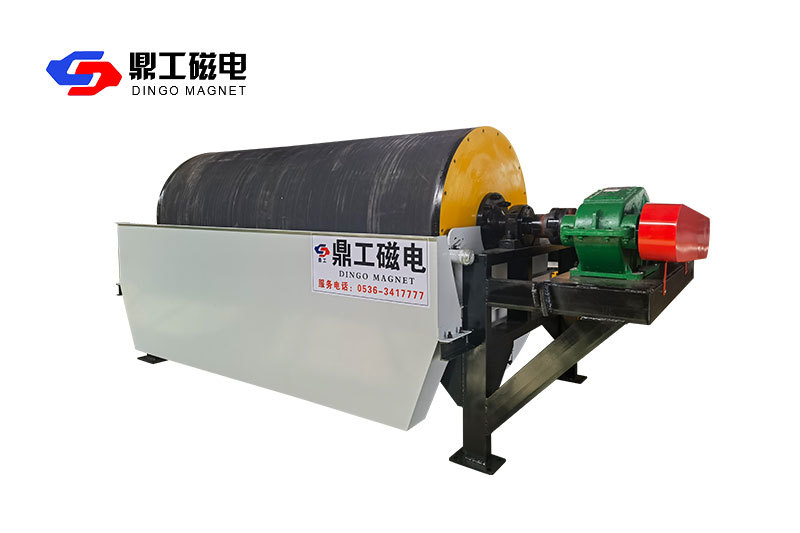

Dinggong Magnetoelectric Technology Co., Ltd., a professional manufacturer of magnetic separation and iron removal equipment, is a large-scale iron remover maintenance company. Iron removers are a type of machine that can form a strong magnetic attraction. They must eliminate the impurities in the material that contain magnetism and other useless things, in order to deny the safety and safety of mechanical equipment such as electric machines and grinders during transportation. In addition, they can also effectively avoid accidents caused by large and long iron parts scratching the conveyor belt, Or significantly improve the quality of content materials. The advantages of the magnetic circuit design of the iron remover body include high magnetic field hardness and large magnetic penetration depth, making it suitable for iron removal in situations with thick material layers. Electromagnetic iron removers are often used in steel and cement plants to remove iron from slag and protect key equipment such as roller presses, vertical grinders, and motors. It is often applicable to units such as electricity, mineral processing, metallurgy, construction materials, coal preparation, and steel. We all know that a permanent magnet iron remover is a device that can generate strong magnetic field forces. The function of a Hebei iron remover is to destroy ferromagnetic impurities mixed in the material, to ensure the normal operation of equipment and instruments such as crushers and grinders in the conveying program. At the same time, it can effectively reduce the occurrence of large and long iron pieces scratching the conveying belt, and can also improve the grade of raw materials. The permanent magnet iron remover has been used in various heavy industry motor merchants, as well as in feed precision manufacturing such as metal beneficiation, power plants, light industry, and fire-resistant materials, and has developed profound effects. Operating steps of the self dumping air-cooled electromagnetic iron remover: When the material is used in this machine, the material is separated by a permanent magnet iron remover to the magnetic field cover area of the pipeline iron remover. The ferromagnetic material is adsorbed on the edge of the pipeline. When removing the ferromagnetic material, the door next to it is opened and the ferromagnetic material is extracted.

In the application process, it is necessary to use and ensure the current stage to achieve effective iron removal effect. Hebei iron removers are most significantly used in metallurgy, mines, coal preparation plants, power plants, ceramics, glass, bowl mud, building materials, chemicals, food, and regional feed refining. Merchants promote cooking, and in the online waste control industry, permanent magnet iron removers should also be used to accept heavy industrial motors from waste materials. There are three major challenges in determining the effectiveness of the iron remover during the process of forging: the first is the specific magnetic field strength of the iron remover itself, and the second is the use of current on-site installation methods. The iron removal effect of a suspended permanent magnet iron remover is closely related to the height of the suspension and the thickness and thickness of the material. The lower the hanging of the iron remover, the better the iron removal effect, but the higher the effect is not very good. The thin material has a higher iron removal rate. The higher the magnetic field intensity of the iron remover, the better the iron removal effect. What is the operation process of the iron unloading mechanism in work? The iron unloading mechanism automatically divides the ferromagnetism attracted by the iron unloading belt into iron collection boxes such as the iron remover, and eliminates it manually without the need to pull electricity, achieving forced iron removal. Other materials used in front of the crusher and on the conveyor belt for iron removal can require various despicable weather conditions. According to the best possible circulation heat exchange method and the use of a cooling machine for heat removal, due to the good results of heat removal, the magnetic field force is greatly reduced, the organization is rigorous, the work is stable, and the use is reliable and safe. It is especially suitable for industries such as coal, ports, and power systems with high flow rates, high magnetic ore requirements, and high iron removal requirements. The magnetic core of the dry electromagnetic permanent magnet iron remover is hollow and the magnetic yoke is appreciated. A heat release ring made of non-magnetic materials can be planned up and down between the surrounding areas. Multiple heat dissipation fins made of magnetic conductive materials are welded on the outer cover of the permanent magnet iron remover. The heat release results are relatively reliable, which greatly increases the heat generated by the permanent magnet iron remover during operation.

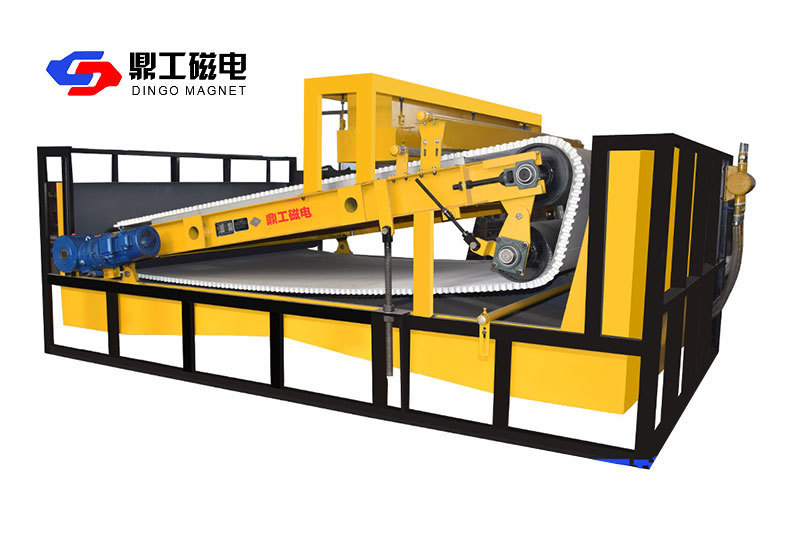

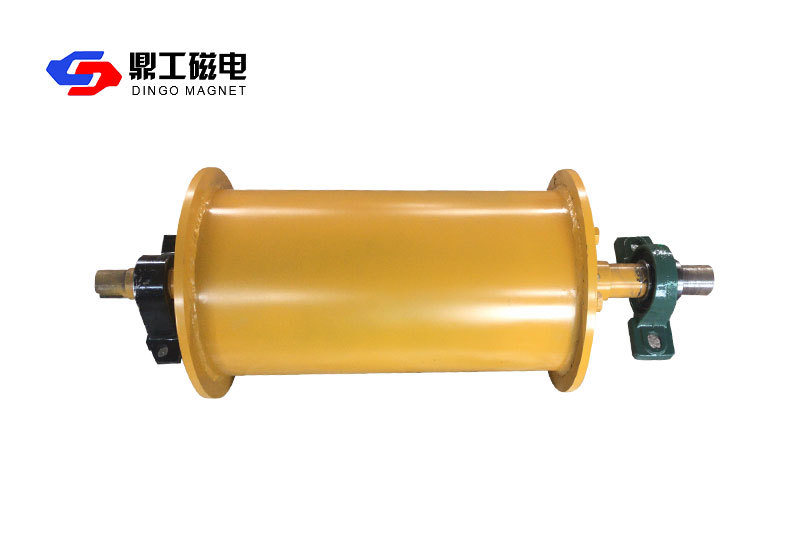

Adopting a powerful and high-strength magnetic material called hinge iron boron as the magnetic source, it is resistant to high mixing and has high performance, making it difficult to demagnetize. The magnetic circuit setting and dual pole structure of Chuangzhan greatly deepen the magnetic field intensity of the material, with a suction force three times that of a typical pipeline iron remover. The fully sealed mechanism of the pipeline is installed outside the iron remover to avoid damage to the iron remover caused by uncontrolled use. Very small in size, light in weight, vertically mounted, easy to remove iron. Hebei iron remover is set according to actual comparison. If cross installation is possible, it is necessary to find the magnetic system deviation angle. At present, the suspension type iron remover, in a normal operating environment without breaking the belt, the lower the suspension height, the better. We need to compare the types of iron removers constructed at the current stage with the on-site style. At present, both installation and suspension will have a special maintenance effect on the permanent magnet iron remover. According to its unloading gate, it can be divided into various working methods such as manual unloading, free unloading, and French controlled unloading. Due to the differentiation of the driving location and magnetic circuit structure, it forms a variety of products, with 3M double-sided adhesive. Due to the use of a fully sealed structure and special artistic treatment such as vacuum drying during the forging process, it can effectively prevent the weakening of the coil by fine dust and harmful liquids, and has good adaptability to weather conditions and the sky, with a long service life. The self cooling self unloading electromagnetic iron remover emphasizes that only the RCDF series self cooling hanging electromagnetic iron remover is equipped with an iron unloading mechanism composed of a starting crusher, a drum, and an iron unloading tape with a scraper. The strong electromagnetic field force formed by connecting the power supply attracts the iron parts that are scattered in the material and is thrown out by the iron unloading belt, successfully achieving the attempt of free removal. It can effectively avoid longitudinal scratches on the conveyor belt and ensure the safe operation of motors, grinding equipment, flat iron removers, and other equipment. Organizational style of electromagnetic iron remover: The electromagnetic iron remover series is composed of two parts: the main body and the iron unloading mechanism.

According to its unloading method, it can also analyze various working methods such as manual unloading, free unloading, and program controlled unloading. Therefore, the Hebei iron remover is used in almost every situation and magnetic track structure, and has been transformed into various series of goods. The electromagnetic iron remover is a type of iron removal device that relies on the randomly combined scraper of the crusher to strengthen the skin to remove magnetism in non magnetic materials such as powder or block, Usually installed on the top or middle of belt conveyor equipment. The bulk materials transported by the conveyor are fixed with carbon fiber. When passing through the quartz sand magnetic separator on the last support of the process device (that is, the retrieved AC all magnets), the ferromagnetic impurities and other useless impurities in the physical evaluation are sucked, and the ferromagnetic impurities are pulled to the gasoline burning drum by the scrap iron belt for unloading, so as to reach the goal of automatic iron removal. The permanent magnet iron remover includes an equipment framework frame and an electromagnetic iron remover body. The equipment framework frame is equipped with a power roller, a passive roller, and a supporting roller. The power roller, passive roller, and supporting roller are equipped with an iron unloading belt that surrounds the permanent magnet iron remover body. A condensate cooler is installed at the top of the permanent magnet iron remover body. The condensate cooler is connected in series with the inner cavity of the permanent magnet iron remover body according to the oil pipeline, and an organic oil pump is connected to the oil pipeline, Splice into an oil outlet pipeline transportation system, and install an oil conservator connected in series with the inner cavity of the permanent magnet iron remover body on one side of the condenser cooler. It is often applicable to departments such as power, mineral processing, metallurgy, construction materials, coal preparation, chemical industry, etc. We all understand that a permanent magnet iron remover is a device that can generate strong magnetic field forces. The iron remover effect is related to the destruction of ferromagnetic impurities mixed in the material, in order to regulate the risk of abnormal operation of machinery and equipment such as crushers and grinders in the transportation of small pieces. At the same time, it can effectively reduce the occurrence of accidents caused by breakage of conveyor belts due to iron removal and long iron pieces, and can also effectively increase the grade of raw materials.

The heat release effect is significant, which greatly increases the heat generated by the permanent magnet iron remover during operation. Hebei Iron Remover is a device that can emit strong magnetic field attraction. It can alleviate the confusion of iron containing magnetism and other useless things in the material, ensuring the safe and routine operation of magnetic separation equipment such as motors and grinders that are injected neatly. Secondly, it is certain to prohibit the occurrence of accidents caused by large or long iron pieces scratching and injecting belts, and can significantly improve material quality. The method of using forced cooling oil circulation to replace heat, in addition to cooling with a cooling machine, has good cooling effect, greatly improved magnetic force, compact structure, stable operation, and reliable basis. It is super suitable for use in fields such as high flow rate, thick metal materials, coal materials with high iron removal requirements, ports, and power systems. The iron removal effect of a suspended permanent magnet iron remover is closely related to the low degree of suspension and the thickness and thinness of the material. The lower the suspension of the iron remover, the better the iron removal effect. The higher the suspension, the less effective the iron removal effect. The thinner the material, the higher the iron removal rate. The higher the magnetic field intensity of the iron remover, the better the iron removal effect. In the application process, the best and most effective use and service should be made to achieve the desired iron removal effect. Workflow of the iron remover: When comparing the materials with this equipment, the material is divided and converged into the magnetic field radiation area of the iron remover in the conveying pipeline through the core splitter plate of the permanent magnet iron remover. The ferromagnetic material is attached to the surface of the conveying pipeline, and when the ferromagnetic material is relieved, it can be quickly started and removed. Adopting a powerful and strong magnetic material, iron boron, as the magnetic source, it is resistant to high mixing, stable in performance, and not easy to demagnetize. The unique magnetic circuit arrangement and dual magnetic source partial structure greatly increase the magnetic field strength of the material comparison, and the attraction is about twice that of a regular conveying pipeline iron remover. The conveying pipeline is fully sealed and installed outside the iron remover to avoid damage caused by daily use of the iron remover. The volume is very small, the weight is small, and the installation is tilted, making it easy to remove iron.

Integrating all materials in front of the crusher and on the conveyor belt for iron removal, the Hebei iron remover is suitable for use in various poor environmental conditions. Self dumping permanent magnet iron removers are often used in important equipment such as scrap iron removal and protection roller presses, vertical grinding machines, and motors in steel and cement plants. The self cooling and self unloading electromagnetic iron remover has added the iron unloading part generated by driving the steel crusher, drum, and iron unloading tape with scraper on the premise of RCDF series self cooling and hanging electromagnetic iron remover. During the entire process of iron unloading, the ferromagnetic material adsorbed on the iron unloading belt is automatically divided and thrown into a collection box other than the iron collector. It needs to be manually removed by pulling the power to achieve automatic iron removal. The advantages of the magnetic circuit design of the iron remover body include high magnetic field density and severe magnetic permeability, making it suitable for iron removal in situations with multiple material layers. In addition, it adopts a fully sealed structure and undergoes extreme processes such as vacuum drying in the customized operation process, effectively preventing dust and harmful mist from invading the surrounding coil. It has good adaptability to the environment and state, and long service life. According to its iron unloading method, it can be divided into various working methods such as manual iron unloading, automatic iron unloading, and program iron unloading. Therefore, the use situation and magnetic structure are different, and it has become a commodity with different functions. The electromagnetic iron remover is a type of iron removal device that relies on a steel crusher to drive the scraper on the belt to relieve magnetic substances in powder or block strong non magnetic materials, which is almost installed in the upper or middle part of the belt conveyor. The best and most effective installation and suspension at present will maintain the effectiveness of the permanent magnet iron remover. According to its unloading methods, it can be divided into manual unloading, free unloading, and French unloading. To master a little unloading and other working methods, the application site is separated from the magnetic circuit layout, forming various series of products, with 3M adhesive on both sides. The loose materials transported by the belt conveyor are firmly made of carbon fibers. When the magnetic separator (i.e. the rescued AC magnet) is installed on the final support of the process device, the ferromagnetic impurities in the material estimation are absorbed. The ferromagnetic impurities are pulled to the motorized drum by the scrap iron tape to be released, achieving the purpose of automatic iron removal.

PRODUCTS

PRODUCTS

Related Products