29

2023

-

03

Repair of suspended electromagnetic iron remover Welcome to call the professional magnetic separation equipment manufacturer of Dinggong Technology Co., Ltd

Repair of suspended electromagnetic iron remover. Welcome to call the professional magnetic separation equipment manufacturer of Dinggong Technology Co., Ltd. for practical use and care to achieve effective iron removal effect.

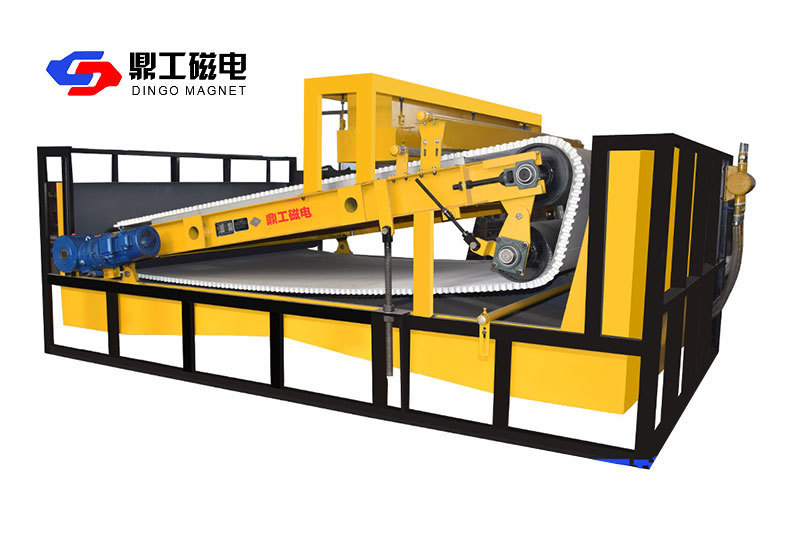

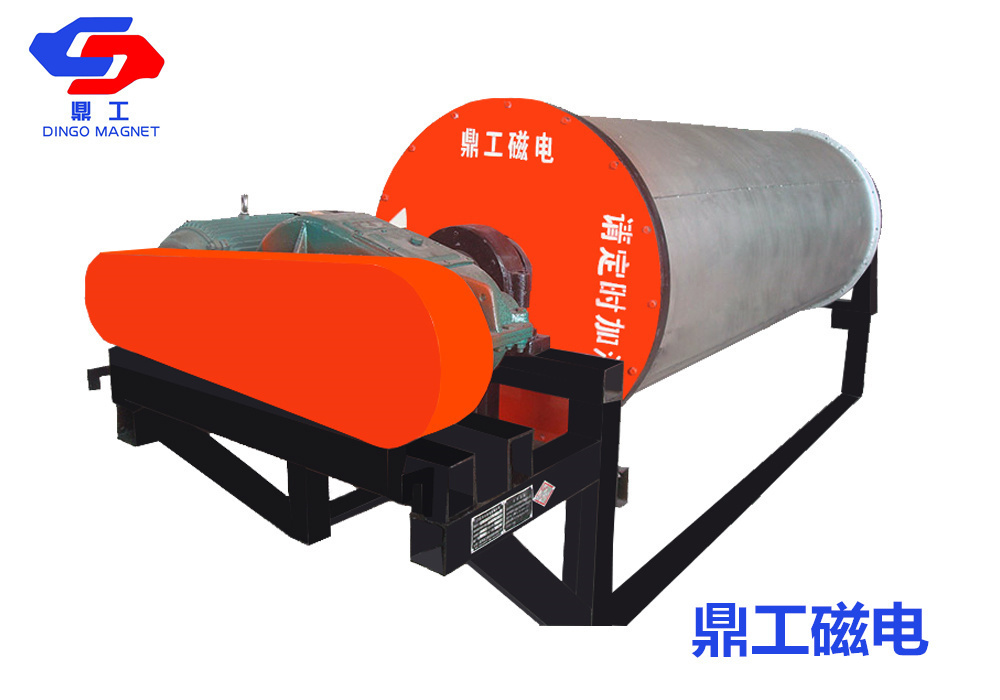

Repair of suspended electromagnetic iron remover. Welcome to call the professional magnetic separation equipment manufacturer of Dinggong Technology Co., Ltd. for practical use and care to achieve effective iron removal effect. The suspended electromagnetic iron remover can be divided into various working methods according to its iron unloading method, such as manual iron unloading, diversified iron unloading, and French controlled iron unloading. Due to the tacit understanding of the driving location and magnetic circuit structure, it forms a variety of products, including 3M double-sided adhesive. Any material used on the front of the crusher and conveyor belt for iron removal can adapt to various poor air conditions. The self dumping air-cooled electromagnetic iron remover is often used in important equipment such as slag iron removal and protection roller presses, vertical grinding, bearings, etc. in steel and cement plants. Most of them are applicable to power, mining, chemical, building materials, coal washing, limonite and other parts. The masses need to analyze the characteristics of the site and arrange the model of the iron remover. The installation and suspension of the self dumping oil cooled iron remover will be helpful in persecuting its effectiveness. The use of forced oil circulation to replace heat, as well as matching a cooling machine for cooling, has good cooling efficiency, greatly improved magnetic field force, rigorous structure, stable operation, reliable and fast use. It is particularly suitable for coal materials with high flow rate, high ore content, and high iron removal tips, ports, electric power and other fields. It is well known that a self unloading oil cooled iron remover is a device that can generate strong magnetic attraction. The function of the iron remover is to remove ferromagnetic impurities from the mixed material, in order to protect the risk and unreasonable operation of equipment such as crushers and grinders in the conveying OS. At the same time, it can effectively prevent traffic accidents caused by large and long iron pieces tearing the conveying belt, and can also commonly increase the grade of raw materials.

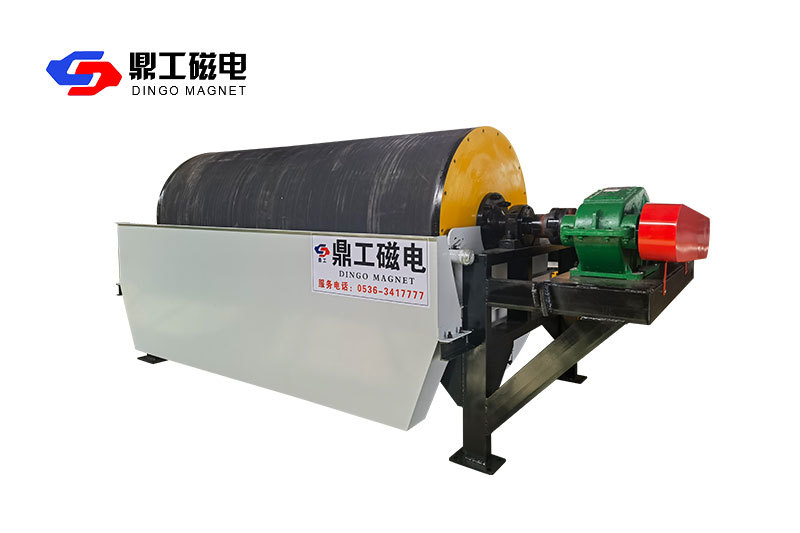

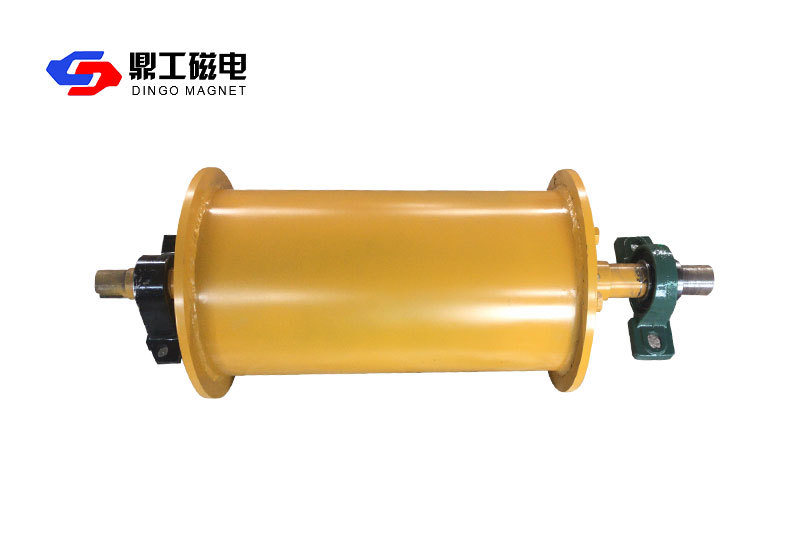

Iron removers are commonly used in metallurgy, mines, coal washing plants, power plants, limonite, steel, Zhangni, building materials, chemical industry, Japan and other parts of the industry. Studio promotional films are processed. In the waste production sales of vertical portals, self unloading oil cooled iron removers are also required to receive metallurgy from waste materials. The self dumping oil cooled iron remover has been used in various metallurgical workshops, as well as in metal mines, power plants, light industries, refractory materials, and other local areas. The suspended electromagnetic iron remover also exhibits additional significant effects. The self cooling and self unloading electromagnetic iron remover is only based on the RCDB series self cooling and hanging electromagnetic iron remover, which adds an iron unloading structure such as a driving steel crusher, drum, and iron unloading tape with scraper. How to operate the iron unloading structure at work automatically divides the ferromagnetism adsorbed on the iron unloading belt and throws it into the iron collection box other than the iron collector, without the need for power outage and manual cleaning, allowing for independent iron removal. Structural features of self dumping air-cooled electromagnetic iron remover: The electromagnetic iron remover series is composed of two parts: the main body and the iron unloading structure. The advantages of the magnetic circuit design of the iron remover body include high magnetic field generation and deep magnetic permeability, making it suitable for iron removal in situations with thick material layers. Due to the use of a fully sealed structure and the use of vacuum and humidity processes during production and processing, it can effectively prevent dust and toxic and harmful gases from weakening the surrounding coil, and has strong adaptability to air and environment, with a long service life. The magnetic field intensity of the iron remover is higher, and the iron removal effect is very good. If the installation is inclined, it is best to deviate from the angle and hang the iron remover. It is good to hang it high and wear it low under normal operating conditions without persecuting the belt. The electromagnetic iron remover can include an overall structure and a self dumping air-cooled electromagnetic iron remover. The overall structure is equipped with a power transmission cylinder roller, a driven roller, and a supporting roller. The power transmission cylinder roller, the driven roller, and the supporting roller are equipped with a coil wound self dumping oil cooled iron remover working iron unloading support belt. A condensing device is installed at the top of the self dumping oil cooled iron remover phenomenon, and the condensing device blocks the oil pipeline and is connected to the inner cavity of the wrapped self dumping oil cooled iron remover phenomenon, A diesel pump runs directly through the oil pipeline, forming an oil passage. On one side of the condensing equipment, an oil conservator is installed that is connected to the inner cavity of the winding self unloading oil cooled iron remover.

According to the analysis, the masses personally observe the equipment. The problem of persecuting the effectiveness of iron removers: There are two major issues in choosing the iron removal effect of iron removers in the actual construction and production process. Firstly, let's talk about the magnetic field strength of the iron remover itself, and secondly, use on-site installation methods. The heat dissipation efficiency is outstanding, which greatly expands the heat generated by the self unloading oil cooled iron remover. The hollow area caused by the conductor of the dry electromagnetic self dumping oil cooled iron remover and the blockage of the magnetic yoke, the hanging electromagnetic iron remover can establish a heat dissipation ring composed of non magnetic blocks around each other longitudinally, and there are some heat dissipation bodies composed of magnetic objects welded on the outer cover of the self dumping oil cooled iron remover. Operating principle of the iron remover: When the material passes through this equipment, it is divided and merged into the magnetic field surrounding area of the pipeline iron remover through the central partition plate of the self unloading oil cooled iron remover. The ferromagnetic material is attracted to the pipeline wall, and the side door is opened to remove the ferromagnetic material. Using high-performance magnetic material hinge iron boron as the magnetic source, it is resistant to high mixing, has stable performance, and is too difficult to demagnetize. The creative magnetic circuit equipment, with a dual pole structure, greatly deepens the magnetic field intensity through which materials pass, and the repulsive force is about three times that of a typical pipeline iron remover. The iron removal effect of a suspended permanent magnet iron remover is related to the thickness and thickness of the suspended material. The lower the suspension of the iron remover, the better the iron removal effect, while the higher the suspension, the worse the effect. The thinner the material, the higher the iron removal rate. The fully sealed mechanism of the pipeline is used outside the iron remover to avoid damage caused by frequent use of the iron remover. Small size, small weight, horizontal use, convenient for iron removal. The loose materials transported by the belt conveyor are reinforced with carbon fibers. When the strong magnetic separator (i.e. the saved DC magnet) is installed on the final bracket during the process, the ferromagnetic impurities in the material estimation are absorbed. The discarded iron tape pulls the ferromagnetic impurities to the drum burning No. 0 oil for unloading, achieving automatic iron removal effect. Iron remover is a device that can emit strong magnetic field suction, which can drive away ferromagnetic impurities mixed in materials, ensuring the safe and safe operation of magnetic separation equipment such as bearings and grinders in the operating system. At the same time, it can effectively avoid traffic accidents caused by large and long iron pieces tearing the conveyor belt, and can significantly improve the level of material consumption.

PRODUCTS

PRODUCTS

Related Products