PRODUCTS

DYXZ series fully automatic iron removal machine

Category:

Tel:

Email:

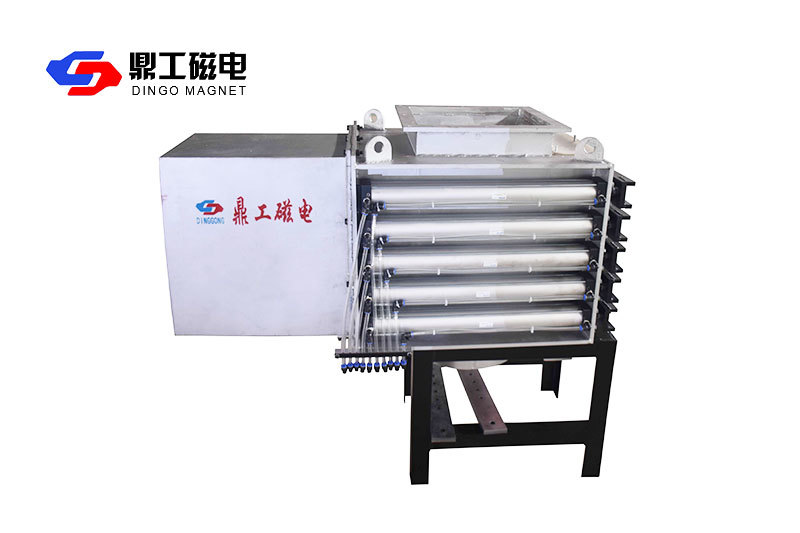

DYXZ series fully automatic iron removal machine

Applicable scope

The DYXZ series fully automatic iron removal machine is mainly used for sorting small iron impurities in powder and fine granular materials. The DYXZ series fully automatic iron removal machine is usually equipped with multiple layers of magnetic grids inside, and the magnetic rods of the upper and lower layers of the grids are arranged in a staggered manner. This design avoids the escape of iron filings from the blind area of the magnetic field, allowing the materials passing through the drawer type iron remover to fully contact the surface of the magnetic rods, more effectively sorting out small iron impurities and pollutants in the materials. This product is widely used in production lines in industries such as food, food additives, pharmaceuticals, feed, fine chemicals, lithium batteries, pigments, carbon black, plastics, etc.

Product mix

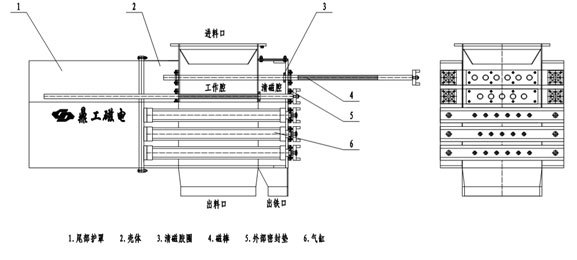

The DYXZ series fully automatic iron removal machine is mainly composed of a shell (feeding port, discharging port, discharging port, working chamber, magnetic cleaning chamber, rear cover), magnetic rod, cylinder, sealing gasket, magnetic cleaning rubber ring, electric control box, etc.

Product Features

1. Automatically clean magnetic materials.

Automatic demagnetization is achieved by driving the magnetic rod through the expansion and contraction of the cylinder.

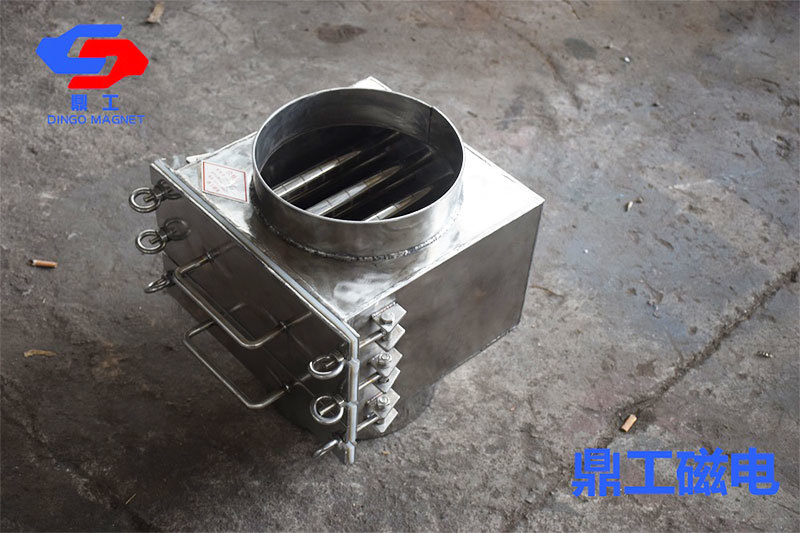

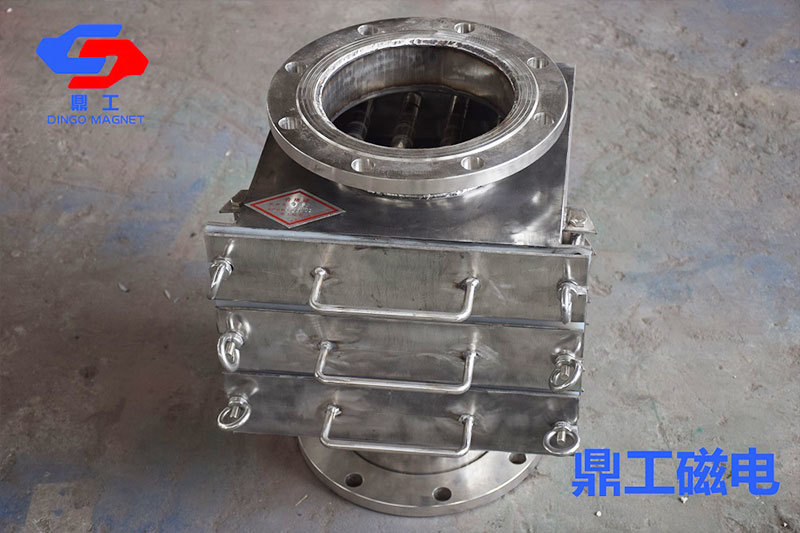

2. The iron unloading method is the iron unloading rubber ring iron unloading method. Compared with the traditional casing iron unloading method, the magnetic field strength of the magnetic rod in this equipment is fully utilized, and the material directly contacts the surface magnetic field of the magnetic rod, which increases the iron removal efficiency by more than twice.

3. Easy installation.

The entire machine is equipped with flange interfaces at both ends for easy installation.

4. The entire machine has strong sealing performance and the working environment is pollution-free.

5. Seal the middle of the working chamber and the magnetic cleaning chamber with a movable rubber ring.

When the magnetic rod is in the working position, the movable rubber ring is closely attached to the partition between the two chambers (working chamber and magnetic clearing chamber), thus blocking the flow of materials between the two chambers, effectively solving the waste of non-magnetic materials falling into the magnetic material unloading chamber. Greatly improves the purity of ferromagnetic impurities and increases the recovery rate of finished products. When the magnetic rod begins to demagnetize, the movable rubber ring gradually separates from the partition and reaches the shell position as the magnetic rod extends outward.

6. The demagnetization time is adjustable and controllable.

The interval time for demagnetization can be adjusted based on the amount of iron impurities in the material.

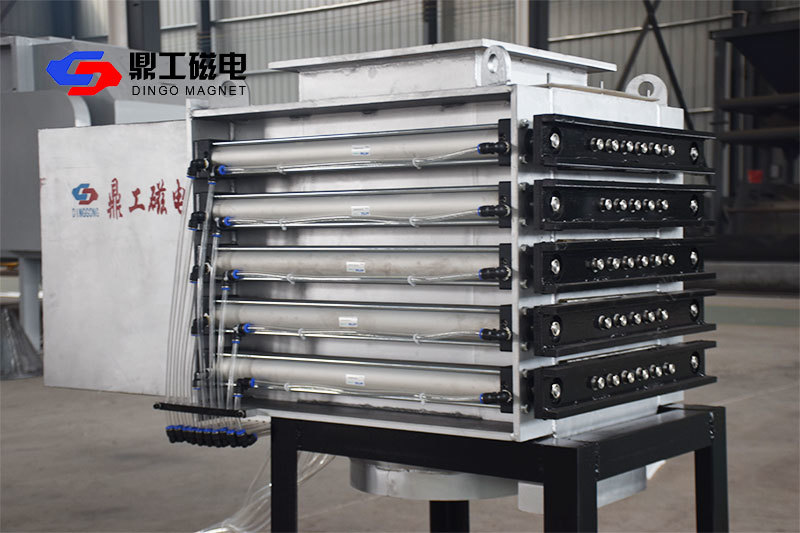

7. Multilayer independent control.

Each layer is an independent individual, controlled separately, and can work alternately during demagnetization.

Working principle

When a material containing a small amount of magnetic iron impurities enters the magnetic separation area of the working chamber from the feeding port, the magnetic iron impurities are firmly adsorbed on the surface of the magnetic rod. After passing through multiple longitudinally staggered magnetic rods, iron impurities are adsorbed clean. Materials without iron impurities enter the next process from the discharge port.

When the iron impurities adsorbed on the surface of the magnetic rod reach the preset automatic demagnetization time, the cylinder starts working, driving the magnetic rod to move towards the cleaning chamber, and then the iron impurities are carried to the cleaning chamber. When the iron impurities adsorbed on the surface of the magnetic rod touch the iron unloading rubber ring in the cleaning chamber, the iron impurities will slowly detach from the magnetic rod. As the magnetic rod continues to extend outward, the iron impurities adsorbed on the surface of the magnetic rod are gradually removed. When the magnetic area in the magnetic rod completely passes through the iron unloading rubber ring, the iron impurities adsorbed on the magnetic rod will be completely cleaned and flow out from the iron outlet. At this point, the cylinder has extended to its maximum, and after 3-4 seconds, the cylinder drives the magnetic rod back to its original position. At this point, the magnetic area of the magnetic rod completely enters the working chamber, and after 8-10 seconds, the second group of magnetic rods starts the demagnetization process until the last group is completed.

Product Selectability

1. Surface treatment: spray coating treatment, mirror polishing, wire drawing polishing, sandblasting treatment.

2. Shell material: stainless steel 201, stainless steel 304, and stainless steel 316.

3. Magnetic strength level of magnetic rod: 8000GS, 10000GS, 12000GS, 13000GS

4. Working temperature: below 80 ℃, 80 ℃, 100 ℃, 120 ℃, 150 ℃.

5. Other special requirements.

Maintenance and upkeep

1. Regularly check whether the standard parts of the cylinder and magnetic rod are loose during each shift.

2. Regularly check the oil mist filter behind the pressure reducing valve. If the oil level is too low, please replenish it in a timely manner.

3. Open the observation port on the top of the magnetic cleaning chamber, regularly check whether the wear of the magnetic cleaning chamber is severe, and whether the cleaning rubber ring is synchronized with the magnetic rod during expansion and contraction.

4. Open the observation port of the rear cover and check if there is any material inside the rear cover. If there is excessive material accumulation, please clean it up in a timely manner.

Related Products