PRODUCTS

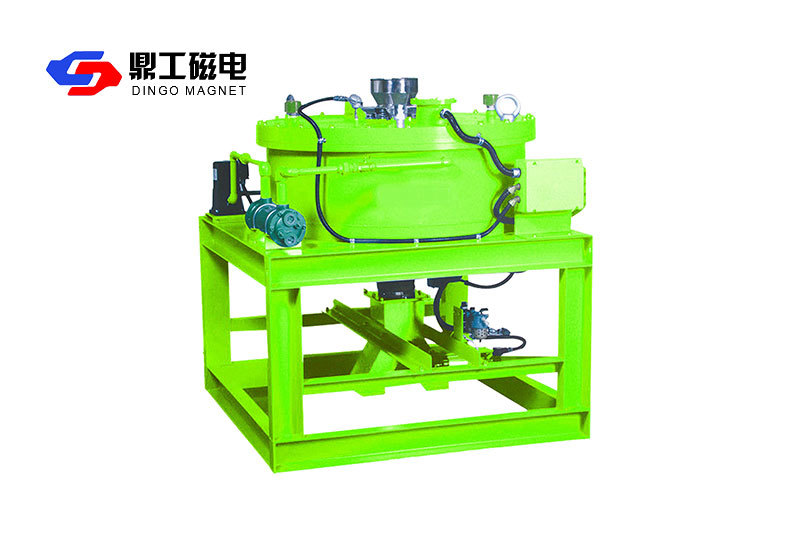

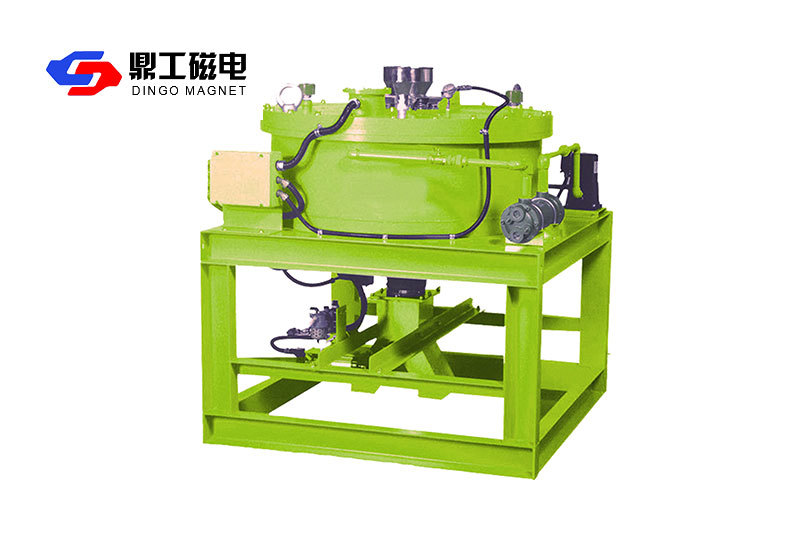

DCFJ series electromagnetic dry powder separator

Category:

Tel:

Email:

DCFJ series electromagnetic dry powder separator

Applicable scope

Remove pollutants such as weak magnetic oxides and filiform rust from fine powder materials. Used for non-metallic minerals such as ceramics, glass, refractory materials, and purified materials in industries such as pharmaceuticals, chemicals, and food.

Technical characteristics

1. Simple connection: During the operation process, the host vibrates, and the input and output of raw materials can be connected through external pipes or canvas bags.

2. Remove fine crops that are not easily circulated: Under the action of a vibrating motor, raw materials with a volume less than 200 microns or high humidity can pass through the sieve uniformly

3. Treatment of high-temperature materials: Standard models can be used to handle raw materials at higher temperatures.

4. Simple installation: As long as the bracket is safe and correct, the device can be installed arbitrarily

5. Convenient cleaning of magnetic filter screen: Place a tray at the outlet of the material to recycle the separated material, and turn off the power to demagnetize the screen for easy cleaning work.

6. Thoroughly separate iron powder from basic materials: Basic materials will never enter the separation box

Product parameters

| Model | DCFJ-300 | DCFJ-350 | DCFJ-450 | DCFJ-600 |

| Magnetic cylinder density | 3T | 3T | 3T | 3T |

| Working chamber diameter | Φ300 | Φ350 | Φ450 | Φ600 |

| Rated current | 18A | 18A | 18A | 18A |

| Total weight of the machine | 1000kg | 1500kg | 2000kg | 2800kg |

| Motor power | 550w×2 | 750w×2 | 1100w×2 | 1500w×2 |

| Excitation power | 7kw | 7kw | 7kw | 7kw |

| Processing capacity | 1-3t/h | 3-4t/h | 4-7t/h | 7-10t/h |

Related Products