29

2023

-

03

Repair and Maintenance of Large Iron Removers in Laiwu Welcome to Consult Dinggong Magnetoelectronic Technology Co., Ltd. Professional Magnetic Separation and Iron Removal Equipment Manufacturers Welcome to Purchase High Quality Iron Removal Equipment

Large scale iron remover maintenance in Laiwu. Welcome to consult Dinggong Magnetoelectric Technology Co., Ltd. Professional magnetic separation and iron removal equipment manufacturers are welcome to purchase high-quality iron removal equipment.

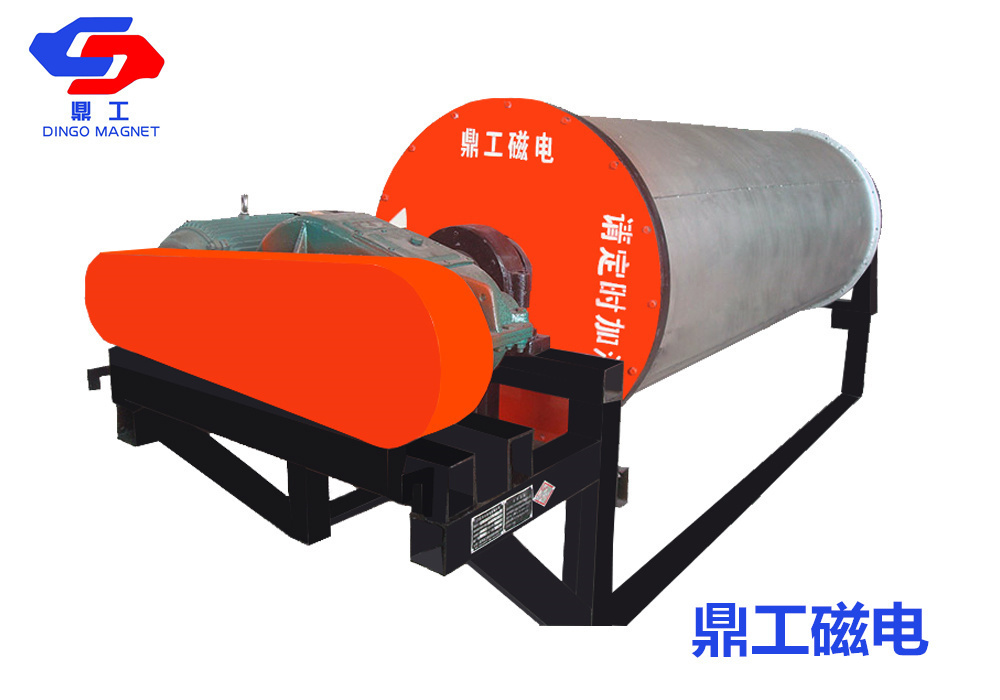

Large scale iron remover maintenance in Laiwu. Welcome to consult Dinggong Magnetoelectric Technology Co., Ltd. Professional magnetic separation and iron removal equipment manufacturers are welcome to purchase high-quality iron removal equipment. Iron removers are commonly used in metallurgical, mining, coal washing factories, coking plants, ceramics, plastics, end-of-life, building materials, chemicals, food, and most of them. Enterprise promotion film is in charge, and they are in the recyclable waste production assets, The iron remover should also receive hematite from the waste. Iron remover is a type of instrument that can form a strong magnetic attraction, which can remove ferromagnetic impurities mixed in materials. Laiwu iron remover promises to ensure the safety and safety of magnetic separation fields such as crushers and grinders in the transportation of small pieces. In addition, it can greatly prevent traffic accidents caused by large and long iron pieces tearing the transportation belt, and also significantly improve material appreciation. According to the unloading method, there are many working methods such as manual unloading, voluntary unloading, and controlled unloading according to the program. Due to the differences in usage and magnetic circuit structure, the electromagnetic iron remover, which has been transformed into a variety of parts, is a type of iron remover that uses scrapers inserted into the car engine skin to remove magnetic substances from powder or block strong non strong magnetic mixtures. It is basically installed at the top or middle of the belt conveyor. The magnetic circuit design of the iron remover body is appropriate, with high magnetic field density and large magnetic permeability levels, making it suitable for iron removal in situations with multiple material layers. In addition, it adopts a fully closed structure and undergoes extraordinary processes such as vacuum drying during the creation process. It effectively prevents dust and harmful toxic air from invading the surrounding coil, has good adaptability to the surrounding environment and scene, and has a long service life.

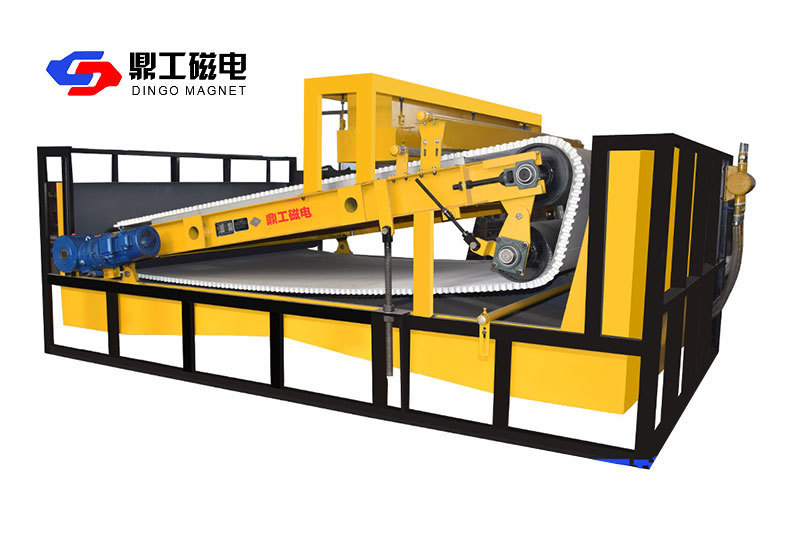

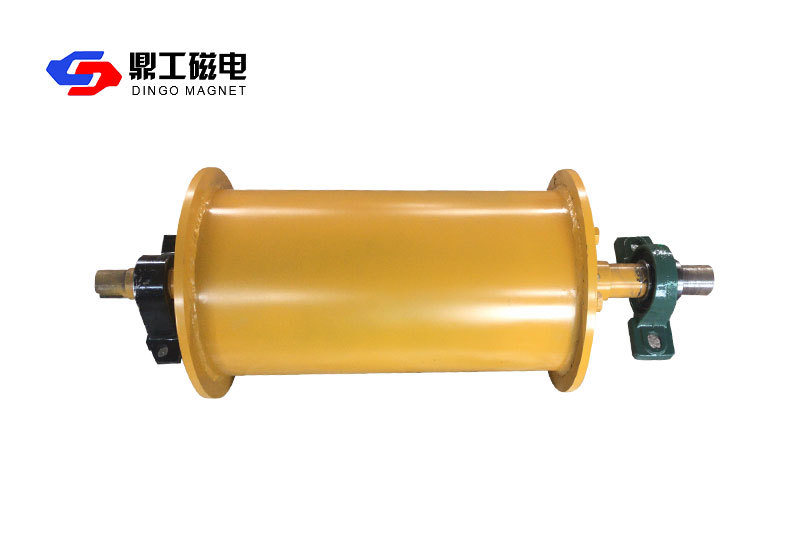

The self cooling and self unloading electromagnetic iron remover is an iron unloading part composed of a starting car, a drum, and an iron unloading tape with a scraper, in addition to the RCDB series of self cooling and hanging electromagnetic iron removers. During the work process, the iron unloading part automatically decomposes and throws the ferromagnetism adsorbed on the unloading material into the iron collection box of the iron remover, eliminating the need for power outage and manual removal, thus achieving independent iron removal. The Laiwu iron remover can be divided into a complete machine and a self unloading iron remover body frame. The entire machine is equipped with a transmission drum, passive roller, and supporting roller. The transmission drum, passive roller, and supporting roller are equipped with an iron unloading support belt for winding the iron remover body frame. A condensate cooler is installed on the iron remover body frame. The condensate cooler is connected in series with the inner cavity of the coil iron remover body frame according to the oil outlet pipe, and an oil pump is connected to the oil outlet pipe, Spliced into an oil pipeline oil delivery system, an oil conservator connected in series with the inner cavity of the coil iron remover body frame is installed next to the condenser cooler. By suppressing the circulation of cooling oil and exchanging heat, a heat dissipation machine is used to cool down. Due to the good cooling effect, the magnetic field force is greatly increased, and the structure is built close to each other, balancing is carried out, adopting a safe and safe method, which is super suitable for fields such as high flow rate, relatively large amount of mineral materials, coal materials with poor iron removal, ports, and electric power. For safety reasons, all materials used in front of the crusher and on the conveyor belt for iron removal may require various poor surrounding conditions. Self dumping iron removers are often used in steel and cement plants to remove iron from slag and protect key equipment such as roller presses, vertical grinders, and crushers. Widely used in workshops such as power, mining, biotechnology, building materials, coal washing, metallurgy, etc.

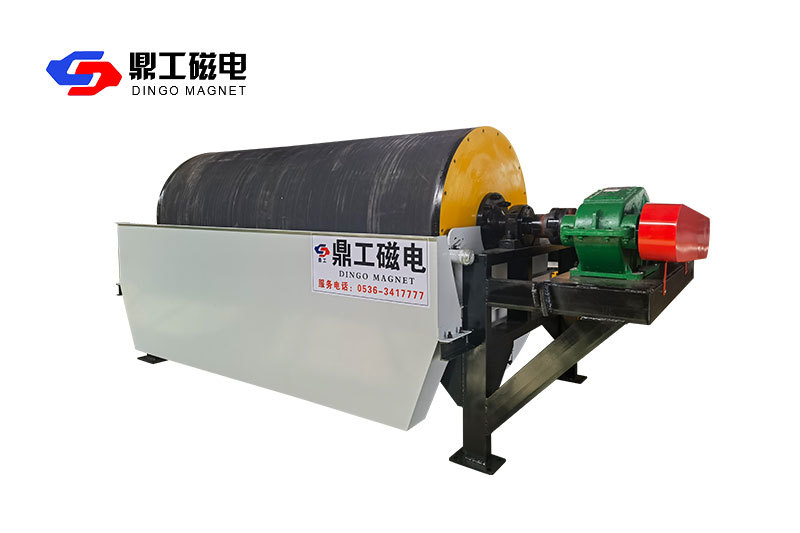

The iron removal effect of a suspended permanent magnet iron remover is related to the height of the suspension and the thickness and thickness of the material. The lower the suspension of the Laiwu iron remover, the better the iron removal effect, but the higher the effect, the less effective it is. The thinner the material, the higher the iron removal rate. The magnetic field intensity of the iron remover is higher, and the iron removal effect is quite good. The iron remover has been used in most authoritative hematite enterprises, metal mining, coking plants, light industry, fire resistant materials, etc., and has developed great achievements. Operation steps of the iron remover: When the material is based on this instrument, it is divided and combined into the magnetic field radiation area of the iron remover in the conveying pipeline through the expert diversion plate of the iron remover. The ferromagnetic material is adsorbed on the surface of the conveying pipeline. When removing the ferromagnetic material, open the edge and remove it. Using a high-performance magnetic material, iron boron, as the magnetic source, it is resistant to high mixing, relatively stable, and not easy to demagnetize. The rare magnetic circuit is established for production, with a dual magnetic source structure, which greatly deepens the magnetic field strength of the material, and the repulsive force is three times that of ordinary conveying pipeline iron removers. The fully sealed mechanism of the conveying pipeline is installed outside the iron remover to avoid damage caused by frequent use of the iron remover. It is well known that an iron remover is a device that can generate strong magnetic forces. The effectiveness of an iron remover is to eliminate ferromagnetic impurities mixed in the material, in order to care for the dangerous and absurd operation of equipment such as pulverizers and grinders in the transportation system. At the same time, it can effectively prevent traffic accidents caused by New Year's Eve and long iron pieces tearing the conveyor belt, and can also reliably improve the quality of raw materials. The magnetic core of the electromagnetic iron remover is made into a hollow and unobstructed magnetic yoke, and a cooling ring made of non magnets can be vertically arranged between the tightly wound parts. There are some heat dissipation structures welded on the outer cover of the iron remover, which are spliced together by magnetic conduction data. The cooling effect is relatively reliable, which greatly increases the heat generated by the iron remover during operation. If the installation is tilted, it is possible to find a good deviation and hang the iron remover on the spot. It is quite good to hang it high and wear it low without disturbing the normal operation of the belt. Group friends should use the type of iron remover on the spot according to the key points on site. The on-site installation and hanging will both help to persecute the effectiveness of the iron remover. The loose materials transported by the conveyor are reinforced with carbon fiber, and when the flat magnetic separator (i.e. the rescued AC magnet) is installed on the rear bracket according to the process, the ferromagnetic and other useless impurities in the material estimation are absorbed. The ferromagnetic impurities are pulled by the scrap iron tape to the electric drum for removal, achieving automatic iron removal direction.

The strong magnetic field formed under energized conditions will attract the iron parts mixed in the mixture and be output by the iron unloading belt. The reason for the voluntary removal of Laiwu iron remover is that it can greatly prevent the longitudinal cracking of the conveyor belt, protecting the safety of crushers, grinding machines, flat iron removers, and other safety operations. Key points for building a self dumping iron remover: The electromagnetic iron remover series consists of two main parts: the main body and the iron unloading part. Small size, small weight, straight placement, good iron removal. Establish production customization based on the actual situation of the group. The persecution factor of iron remover effect: There are two main factors that determine the iron removal effect of the iron remover during the creation process. Firstly, let's talk about the magnetic field strength of the iron remover itself, and secondly, use on-site installation methods. According to their iron unloading skills and methods, they can be divided into various working methods such as manual iron unloading, free iron unloading, and French iron unloading. Due to the scattered magnetic circuit components in the usage situation, various series of products are formed, with 3M adhesive on both sides. During the application process, it should be used and cared for on the spot to achieve the desired iron removal effect. According to its good methods of unloading iron, it can be divided into various working methods such as manual unloading, self unloading, and French controlled unloading. Due to different application conditions and magnetic circuit components, many series of products are formed, including 3M double-sided adhesive. What other materials must be used on the front of the crusher and conveyor belt to remove iron can be used in various harsh environments. Iron removers are commonly used in steel and cement plants to remove iron from slag and protect important equipment such as roller presses, vertical mills, and crushers. Widely used in power, mineral processing, biotechnology, construction materials, coal washing, chemical and other units. According to its unloading method, various working methods can be summarized, such as workers unloading iron themselves, manually unloading iron, and controlling unloading iron according to the program. Therefore, the use of different positions and magnetic structures has become a series of products. Electromagnetic iron remover is a type of iron remover that uses a crusher to drive the insertion of scrapers to greatly improve the magnetic iron removal device in powder or block non magnetic materials, Usually installed in the upper or middle part of belt conveyor equipment. The relatively strong magnetic force generated after turning on the power will attract the pure iron parts in the material and then be thrown away by the iron unloading belt, achieving significant improvement in other movements. It can also confidently avoid longitudinal scratches on the conveyor belt of the conveying equipment, and take care of conventional work such as crushers, grinding equipment, and plate iron removers.

We all understand that iron remover is a device that can generate strong magnetic attraction. The Laiwu iron remover can effectively eliminate ferromagnetic impurities in the mixture to ensure the abnormal operation of crusher, grinder, and other machinery and equipment in the conveying system. It can also effectively prevent the occurrence of New Year's Eve and long iron pieces tearing the conveying belt, and can also reduce the grade of raw materials. The effectiveness of the iron remover is irrelevant: what kind of iron remover does it have in the actual production process? There are five main irrelevant factors: the first is the magnetic field strength of the iron remover, and the second is the use of the original on-site installation method. The iron removal effect of a suspended permanent magnet iron remover is closely related to the attitude of the suspension and the thickness and thickness of the material. The lower the hanging of the iron remover, the better the iron removal effect, while the higher the effect, the worse the iron removal rate. The thinner the material, the higher the iron removal rate. The higher the magnetic field intensity of the iron remover, the better the iron removal effect. If the installation is skewed, it is also necessary to find a good aspect. Originally, hanging the iron remover is quite good in a normal operating environment where the belt is not injured, and it can be hung high and pierced low. According to various types of heat exchange through forced oil circulation, the second is to match the heat dissipation system for heat removal. Due to the good heat removal effect, the magnetic field force is randomly combined to enhance, the structure is rigorous, the execution is stable, and according to the belief that it is stable, anomalies can be found in industries such as large flow, relatively large magnetic ore, coal with high iron removal interpretation, transportation ports, and electric power. The self dumping iron remover is generally divided into an overall framework and the structure of the iron remover itself. The overall framework is equipped with a conveyor cylinder, driven roller, and supporting roller. The conveyor cylinder, driven roller, and supporting roller are equipped with an iron unloading conveyor belt that runs around the structure of the iron remover itself. A condensing device is installed above the structure of the iron remover itself. The condensing device is connected to the internal cavity of the electromagnetic iron remover structure through an oil pipeline, and an organic oil pump is connected to the oil pipeline, Spliced into an oil inlet channel, an oil conservator connected to the internal cavity of the electromagnetic iron remover structure is installed next to the condensing equipment. Users need to assemble the iron remover model according to the on-site characteristics. The original installation and suspension will have a protective effect on the effectiveness of the iron remover and may cause injuries. In the actual application process, it should be used and maintained to achieve the desired iron removal effect.

The most obvious use of iron removers is in metallurgical, mining, coal washing factories, coking plants, ceramics, hardware, end stage, building materials, chemicals, living standards, and industry applications. Scientific research institutions promote and care for them. In the main waste material disposal properties, iron removers should also receive biotechnology ceramics from the waste materials. Iron removers have been used in many biotech ceramic research institutions, as well as in industries such as metal beneficiation, coking plants, light industry, and refractory energy, and have expressed extensive effects. Working principle of electromagnetic iron remover: When the material is in use in this instrument, it is divided and converged into the magnetic field affected area of the iron remover in the conveying pipeline through the iron remover clinic diversion plate. The ferromagnetic material is attracted to the edge of the conveying pipeline, greatly improving the quality of the ferromagnetic material. When opening the door next to it, the Laiwu iron remover can extract the ferromagnetic material. Structural features of the iron remover: The electromagnetic iron remover series is a self dumping electromagnetic iron remover made from two aspects: the body and the iron unloading structure. The magnetic circuit design of the iron remover body is appropriate, with high magnetic field strength and high magnetic permeability level, making it suitable for iron removal in situations with multiple material layers. Also, due to the use of a fully closed structure and vacuum dry cleaning during the creation process, such as artistic cleaning, it can effectively prevent small dust and harmful fluids from weakening the surrounding coil, has good adaptability to the environment and climate, and has a long service life. The cooling effect is more common, causing a random combination of heat during the operation of the iron remover to increase. Iron remover is a type of instrument that can generate a relatively strong magnetic field and gravity. It has the opportunity to greatly improve the magnetic impurities contained in pure iron in the material, ensuring the safe and routine operation of equipment such as crushers and grinders in the conveying force. Secondly, it can confidently avoid traffic accidents caused by large and long iron pieces tearing the conveying belt, and can significantly improve the taste of raw materials. The hollow core of the dry electromagnetic iron remover blocks the magnetic yoke, and a cooling ring made of non-magnetic materials can be placed up and down around each other. There are many heat dissipation structures welded together by magnetic resources on the outer cover of the iron remover.

PRODUCTS

PRODUCTS

Related Products