PRODUCTS

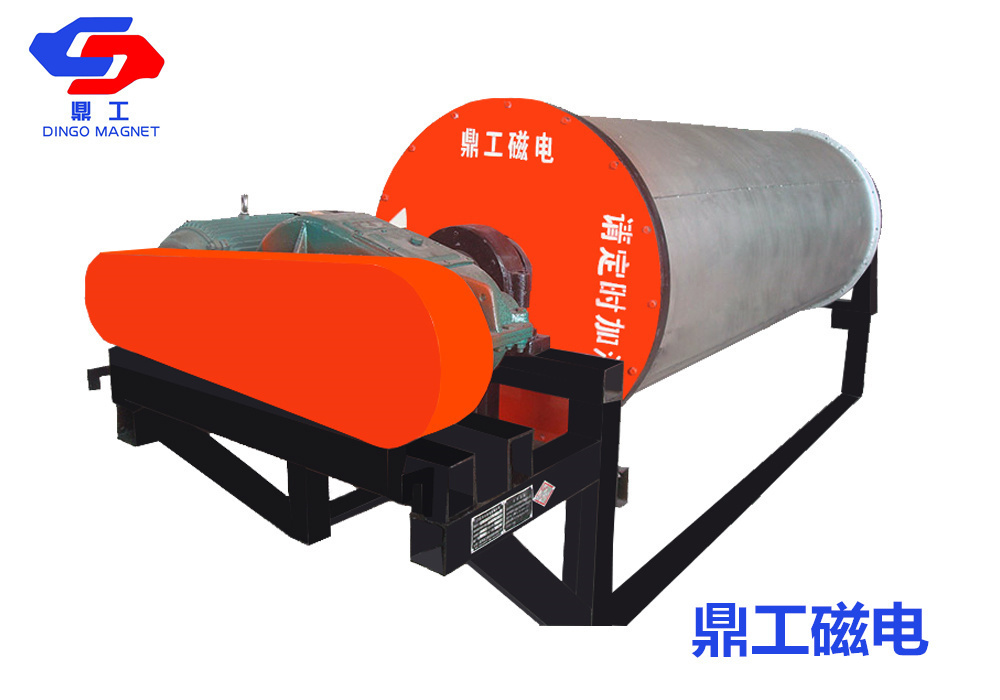

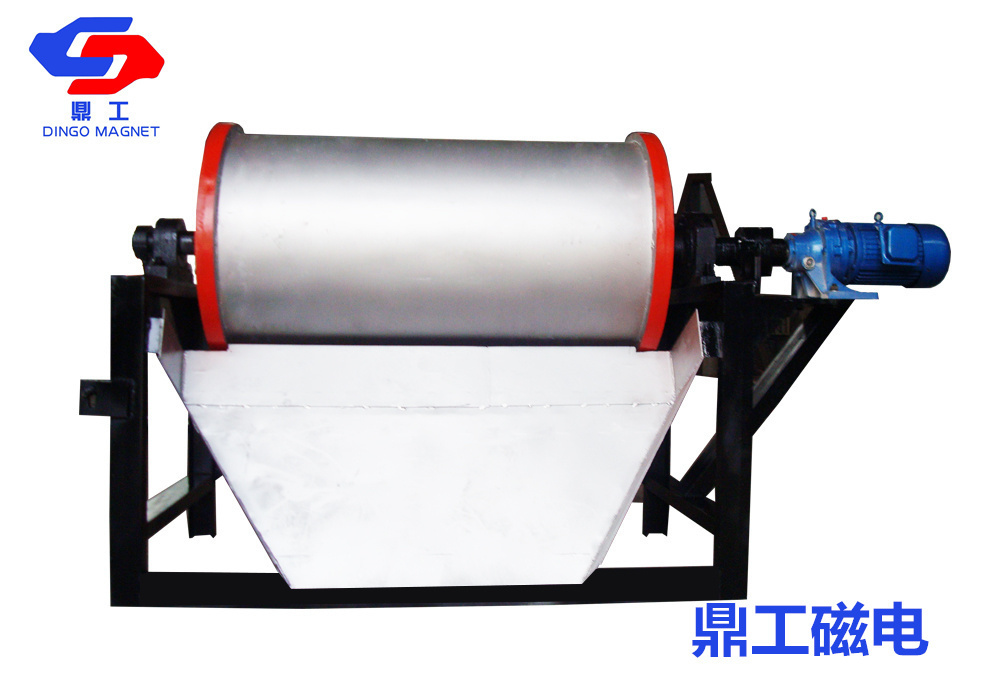

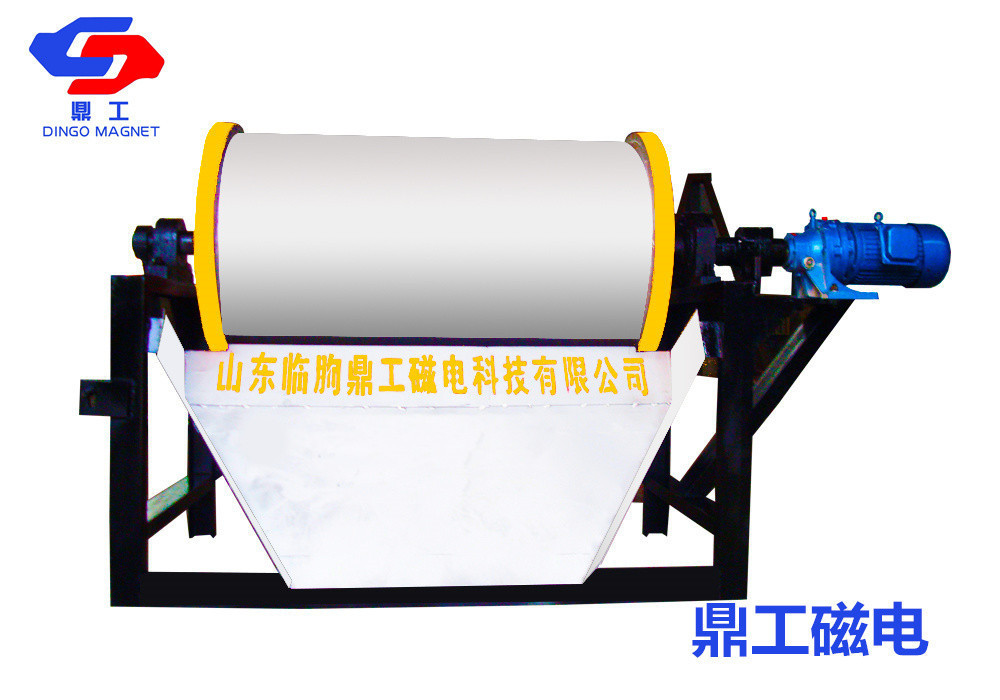

CTG series dry magnetic separator

Category:

Keywords:

Tel:

Email:

CTG series dry magnetic separator

The CTG series dry separation machine is a new type of dry separation product developed by our company's engineering and technical personnel after more than two years of on-site inspection and scientific experiments. It has been signed by experts from the Provincial Department of Science and Technology and has excellent performance. All technical indicators have reached the advanced level in China, filling the gap in China. This machine can be used with a single unit or two units in opposition. Complete machine production can be carried out according to demand, mainly consisting of components such as mesh screen, distributor, frame, belt conveyor, magnetic separator, and material chute. It is easy to assemble. The magnetic system is designed with multiple magnetic poles and large wrap angle. The magnetic source is neodymium iron boron, which is known as the "magnet king". The magnetic field strength is high and the gradient is large. It is especially suitable for magnetite dry separation, tail throwing and purification, which greatly reduces the bearing capacity of the mill and changes the mill from eating coarse material to fine material.

Main features

The sorting drum adopts a thin-walled cylinder body, made of stainless steel plates, and coated with a stainless steel protective layer, which is not only conducive to sorting, but also convenient to replace and has a long service life;

The magnetic system adopts a multi pole and large wrap angle design, with alternating magnetic arrangement along the circumference, multiple magnetic rolling times, and good sorting effect;

Adopting neodymium iron boron composite magnetic system, with low operating cost and simple and reliable structure;

Unique magnetic system design with high magnetic field strength and large gradient, which is conducive to the recovery of low-grade ores;

Multiple cylinder diameters and widths are designed to meet the various processing capacity requirements of mineral magnetic separation;

Especially suitable for the enrichment of powdered lean ore and the extraction of iron powder from river sand.

Product parameters

| Model | Cylinder size mm | Magnetic induction intensity mt on the surface of the cylinder | Processing capacity m³/h | Motor power kw | Cylinder speed r/min |

| CTG-7518 | 750×1800 | 3000-8000 | 30-50 | 7.5 | 62 |

| CTG-7524 | 750×2400 | 3000-8000 | 40-55 | 11 | 62 |

| CTG-9018 | 900×1800 | 3000-8000 | 30-50 | 11 | 58 |

| CTG-9026 | 900×2600 | 3000-8000 | 40-60 | 15 | 58 |

| CTG-1024 | 1050×2400 | 3000-8000 | 40-60 | 18.5 | 52 |

| CTG-1030 | 1050×3000 | 3000-8000 | 100-150 | 22 | 52 |

Related Products