29

2023

-

03

The editor of Shandong Dinggong Magnetoelectric Equipment Factory introduces the potassium feldspar iron removal equipment to you

Potassium feldspar is mainly used in the production of potassium fertilizers, and is widely used as a cosolvent in industries such as glass and ceramic manufacturing.

Scope of application of potassium feldspar magnetic separator:

Potassium feldspar is mainly used in the production of potassium fertilizers, and is widely used as a cosolvent in industries such as glass and ceramic manufacturing. The processing principle of potassium feldspar is to calcine additional ingredients at high temperature to destroy the original structure of potassium feldspar, and then extract potassium salt using leaching method. The potassium feldspar beneficiation equipment mainly includes jaw crushers, ball mills, spiral chutes, shakers, iron removal magnetic separators, flotation machines, and mica removal equipment.

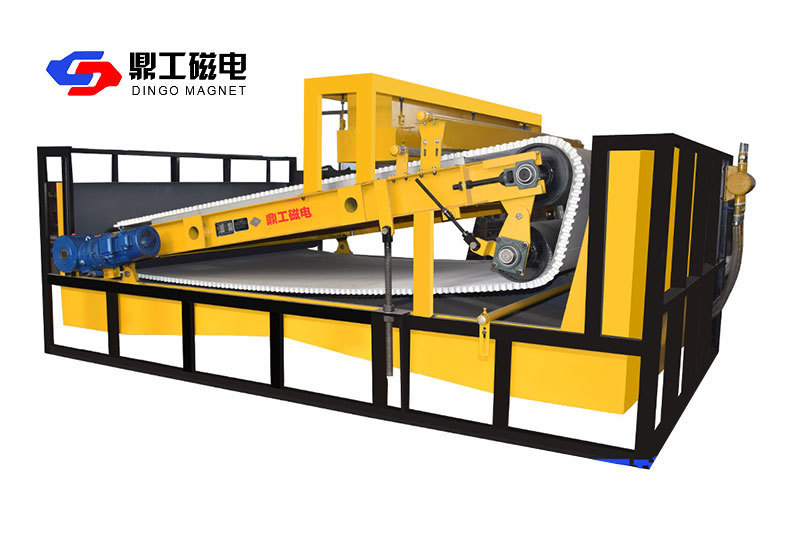

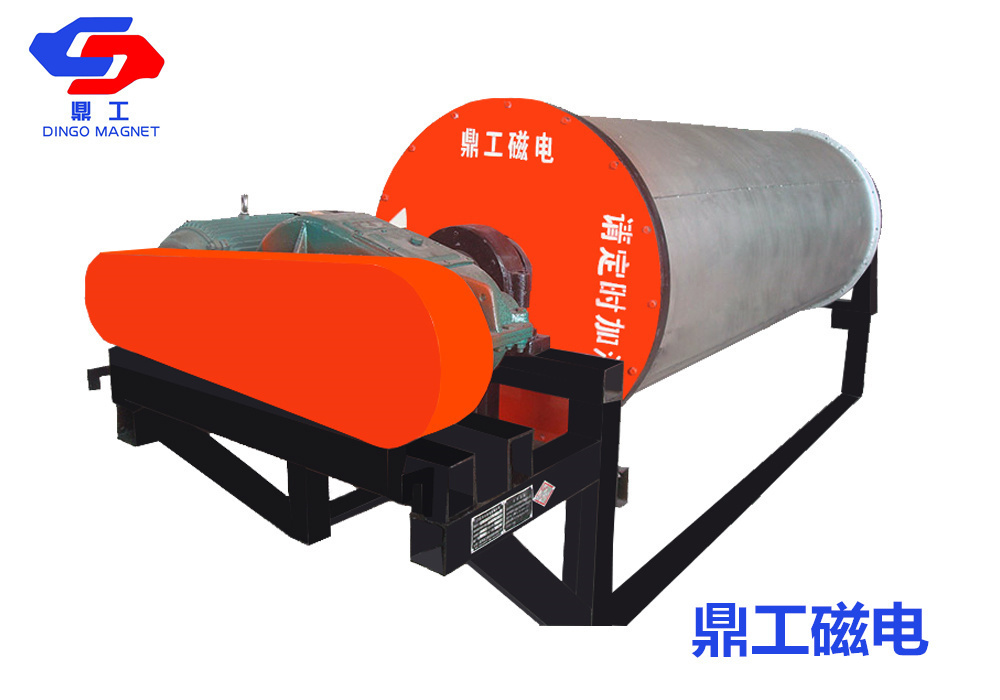

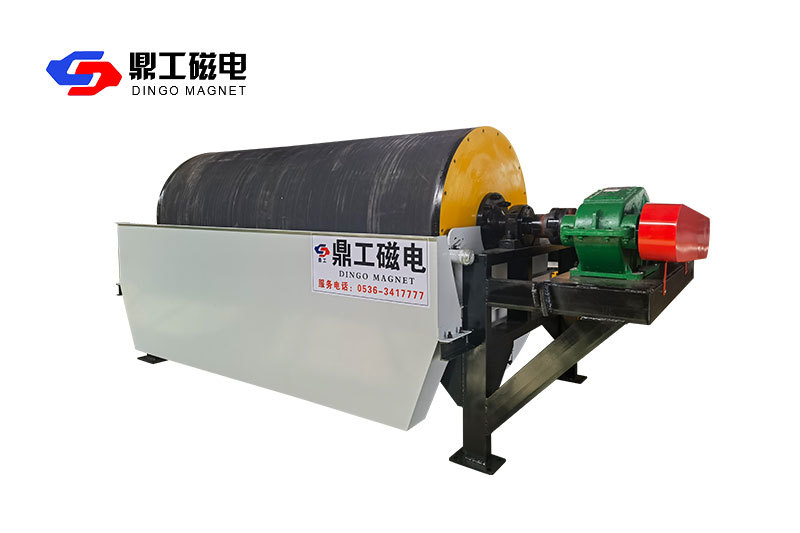

Advantages of potassium feldspar iron removal magnetic separator

1. Multi stage magnetic separation: Multi layer flipping causes iron and iron oxide impurities to undergo repeated flipping and displacement during the movement of the material layer, giving iron and iron oxide more opportunities to touch a strong magnetic field and be thrown out, and then completing the intention of separation.

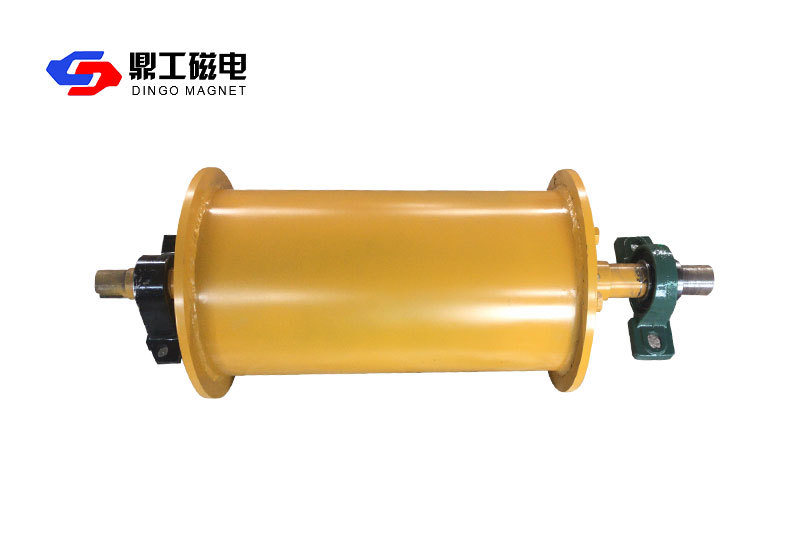

2. Integrating energy conservation and environmental protection: The magnetic drum adopts permanent magnets, and the magnetic field does not consume electricity; The entire machine adopts a fully enclosed dustproof layout, and the outer shell steel plate and other materials are made of anti magnetic stainless steel, which is beautiful and elegant, with a good working environment and a small footprint.

3. Good separation effect of magnetic separation: it can separate the iron impurities that were originally guessed at once, so that the iron content target of the refined powder material can meet the needs of users at once. After adjustment, it can obtain high-quality refined powder that meets the needs of different users.

4. Actively separating and collecting iron oxide impurities: Iron and iron oxide impurities are adsorbed on the surface of the magnetic drum under the action of magnetic field force, and when they move out of the magnetic field action zone, they fall off the surface of the magnetic drum and fall into the impurity collection hopper under the action of gravity. The entire process is progressing one after another, and the system is stable and reliable.

5. If the iron removal magnetic separator is used in conjunction with our potassium feldspar coarse powder (30-100 mesh) Raymond mill, it has an iron removal effect.

PRODUCTS

PRODUCTS

Related Products