PRODUCTS

XB series mixing bucket

Category:

Keywords:

Tel:

Email:

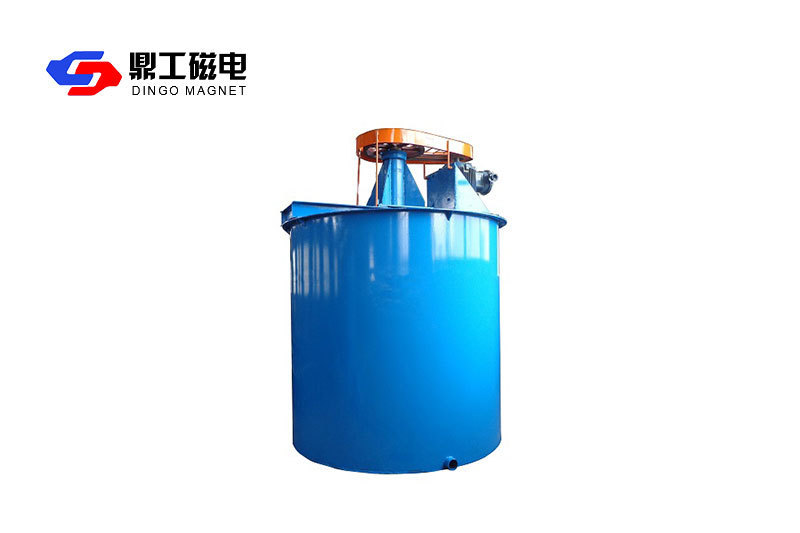

XB series mixing bucket

The stirring bucket is a necessary equipment driven by a triangular belt drive of an electric motor to rotate the impeller, fully and evenly mixing drugs and slurry, increasing the reaction time of drugs and enhancing the quality of drug reactions. This machine is suitable for mineral processing and can also be used for mixing various chemical industry cakes.

The mixing bucket is composed of components such as an electric motor, impeller, stator, bearings, etc. It adopts a flat bottomed barrel shaped radial circulation spiral impeller mechanical mixing method for mixing operations. When the stirring tank is working, the electric motor pulls the triangular belt transmission device to drive the impeller to rotate. Under the uniform stirring action of the impeller, the slurry and reagents achieve full mutual mixing, increasing the reaction time of the reagents to the slurry, strengthening the reaction quality of the drugs, and thus enabling the materials to be fully stirred and mixed, making necessary preparations for the next stage of flotation machine production.

Technical characteristics

The structure is compact, with good sealing performance, and an ash baffle is set at the feed inlet to prevent water mist from flowing back.

Stir evenly, with fan-shaped stirring blades and a large contact area with the medium during stirring.

The nozzles are arranged in multiple rows, with uniform and adjustable water flow.

The residual ash rate is low, and the setting of the watershed at the bottom of the box ensures that there are no dead corners inside the equipment.

The mining mixing drum equipment has advanced performance, stable finished product quality, uniform mixing, and rapid discharge.

Scope of application

This machine is set up to fully mix and contact the reagents with the ore slurry before flotation operations, in order to maximize the effectiveness of the reagents. It is suitable for stirring the pulp and flotation reagents with a concentration not exceeding 30% and an ore density not exceeding 3.5.

Product parameters

| Specification and model | Internal dimensions of the tank body | Effective volume (m³) | Agitator | Electric machinery | Total weight(kg) | |||

| Diameter (mm) | Depth (mm) | Diameter (mm) | Speed (r/min) | Model | Power (kW) | |||

| XB-750 | 750 | 750 | 0.26 | 240 | 530 | Y90S-4 | 1.1 | 550 |

| XB-1000 | 1000 | 1000 | 0.58 | 240 | 530 | Y90L-4 | 1.5 | 700 |

| XB-1200 | 1200 | 1200 | 1.14 | 400 | 320 | Y100L2-4 | 3 | 980 |

| XB-1500 | 1500 | 1500 | 2.2 | 400 | 320 | Y100L2-4 | 3 | 1330 |

| XB-2000 | 2000 | 2000 | 5.46 | 550 | 230 | Y132M2-6 | 5.5 | 2100 |

| XB-2500 | 2500 | 2500 | 11.2 | 650 | 200 | Y160L-6 | 11 | 3438 |

| XB-3000 | 3000 | 3000 | 19.1 | 700 | 210 | Y225S-8 | 18.5 | 5100 |

| XB-3500 | 3500 | 3500 | 30 | 850 | 230 | Y225M-8 | 22 | 7900 |

Related Products