16

2025

-

11

Magnetic Separation: Unlocking the Power of Attraction

Discover engaging examples of magnetic separation and how this powerful technique is applied in various industries.

The Magic of Magnetism

Have you ever wondered how some materials can be pulled apart with just a magnet? It's like magic, but it's rooted in science! Today, we're diving into examples of magnetic separation, a fascinating method used in various industries to separate magnetic materials from non-magnetic ones.

What is Magnetic Separation?

Magnetic separation is a process that uses magnets to remove magnetic materials from a mixture. This technique is widely used in recycling, mining, and even food processing. It's efficient, cost-effective, and, let's face it, pretty cool!

Why It's Important

So, why should you care about this? Well, magnetic separation helps in purifying materials, reducing waste, and enhancing product quality. Plus, it's eco-friendly! Who doesn't want to save the planet while getting the job done?

Examples of Magnetic Separation in Action

Now, let's get into the nitty-gritty with some real-world examples of magnetic separation. These will give you a clearer picture of just how versatile this method can be.

1. Recycling Scrap Metal

One of the most common examples is in the recycling industry. Ever seen a giant magnet swoop down on a pile of scrap metal? That's magnetic separation at work! These magnets effectively pull out ferrous metals like iron and steel, making the recycling process smoother and more efficient.

2. Mining Operations

In the mining sector, magnetic separation is crucial for extracting valuable minerals. For instance, iron ore is often subjected to this technique to remove impurities. As a result, miners can obtain a higher quality product, which is a win-win!

3. Food Industry Applications

Believe it or not, magnetic separation is also used in food processing! It helps to ensure that products are free from metal contaminants. Imagine biting into a delicious chocolate bar only to find a piece of metal—yikes! Thanks to magnetic separation, food safety is greatly enhanced.

The Science Behind the Separation

Alright, let's geek out a bit. The principle behind magnetic separation is relatively straightforward. Magnets attract ferromagnetic materials, which are materials that can become magnetized. When a mixture passes through a magnetic field, the magnetic particles stick to the magnet, while the non-magnetic materials fall away.

Different Types of Magnetic Separators

There are several types of magnetic separators, each designed for different applications. Let's break it down:

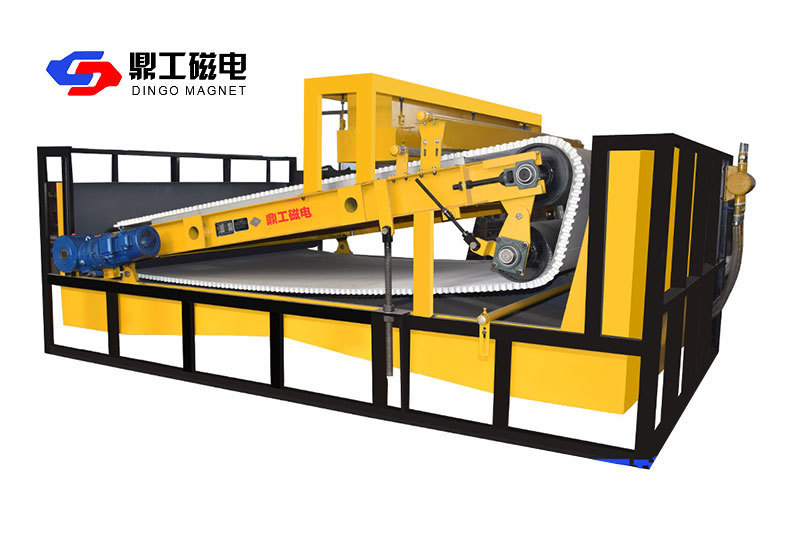

- Overband Magnetic Separators: Commonly used in conveyor systems to remove ferrous materials.

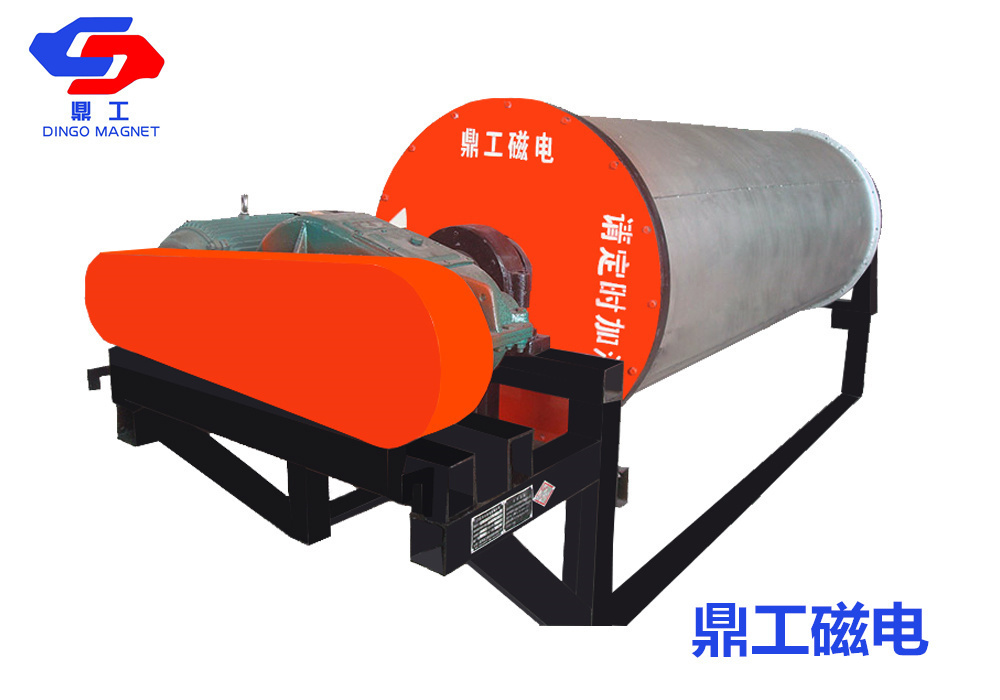

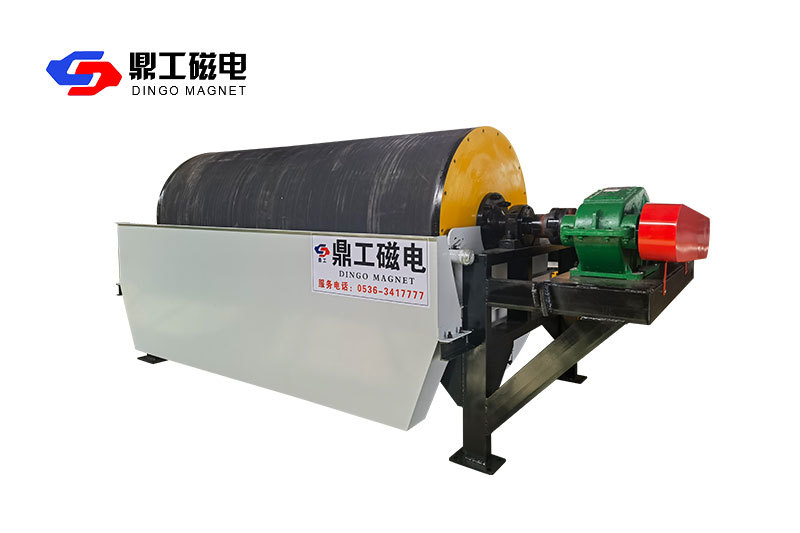

- Magnetic Drum Separators: These are effective for bulk materials and can continuously separate metals.

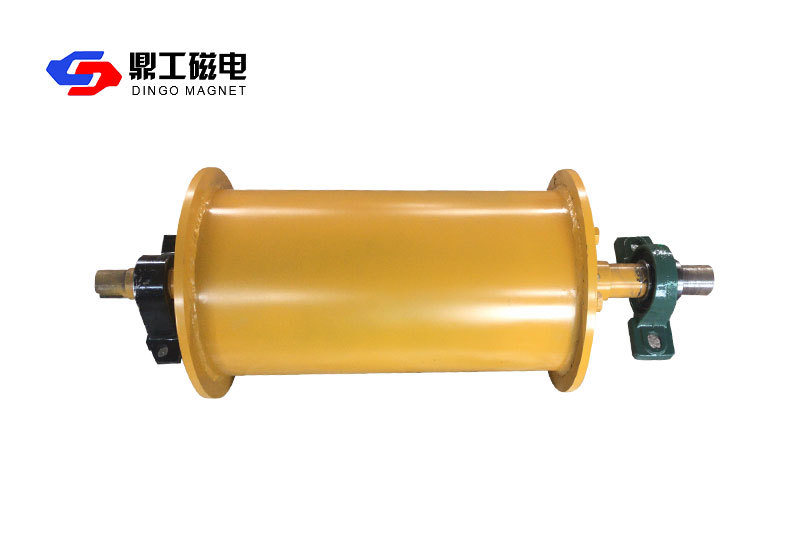

- Magnetic Pulleys: Used at the end of conveyor belts to automatically remove unwanted metals.

Challenges and Innovations

While magnetic separation is incredibly beneficial, it does come with its challenges. For instance, the effectiveness of magnetic separation can vary based on the size and type of the materials involved. However, advances in technology are paving the way for more efficient magnetic separators.

The Future of Magnetic Separation

As industries continue to evolve, so does the technology behind magnetic separation. Innovations like high-intensity magnetic separators are being developed to tackle more complex materials. This means we can look forward to even better recycling processes, cleaner mining operations, and safer food production.

Wrapping Up

In conclusion, examples of magnetic separation highlight the importance of this method across various industries. From recycling and mining to food safety, magnetic separation is a game-changer that continues to evolve. So, next time you see a magnet in action, remember: it's not just a toy; it's a powerful tool making our world a better place!

examples of magnetic separation

PRODUCTS

PRODUCTS

Related Products