15

2025

-

11

The Unsung Heroes of the Food Industry: Magnetic Separators

Discover how food industry magnetic separators are vital for safety and quality in food production.

Introduction: The Hidden Guardians

Every time you bite into that delicious apple or savor a slice of freshly baked bread, you might not realize the unseen forces at play ensuring your food is safe. One of the most critical players in the food industry is the food industry magnetic separators. These devices, often overlooked, are essential for maintaining quality and safety in food processing. Let's dive into their world and explore why they are more than just metal detectors.

What Are Magnetic Separators?

So, what exactly are food industry magnetic separators? Simply put, they are tools designed to remove metal contaminants from food products. Whether it's a tiny shard of metal from machinery or a misplaced clip from a worker's uniform, these separators ensure that what ends up on your plate is free from potential hazards. Talk about peace of mind!

Why They Matter: Safety First!

Imagine biting into a sandwich and discovering a piece of metal. Yikes! That's where food industry magnetic separators come in. They play a crucial role in food safety, protecting both consumers and manufacturers. By preventing metal contamination, they help businesses comply with safety regulations and maintain their reputation. After all, no one wants to be the talk of the town for the wrong reasons, right?

The Impact on Quality Control

Beyond safety, these magnetic separators are vital for quality control. In an industry where consistency is key, ensuring that food products are free from contaminants not only protects the consumer but also enhances the overall quality of the product. Companies that utilize these separators often find that their products stand out in a crowded market. It's a win-win!

Types of Magnetic Separators Used in Food Processing

Now, let's get down to the nitty-gritty. There are various types of food industry magnetic separators tailored for different applications:

- Magnetic Grates: Often installed above chutes or hoppers, magnetic grates capture ferrous metal particles as ingredients flow through.

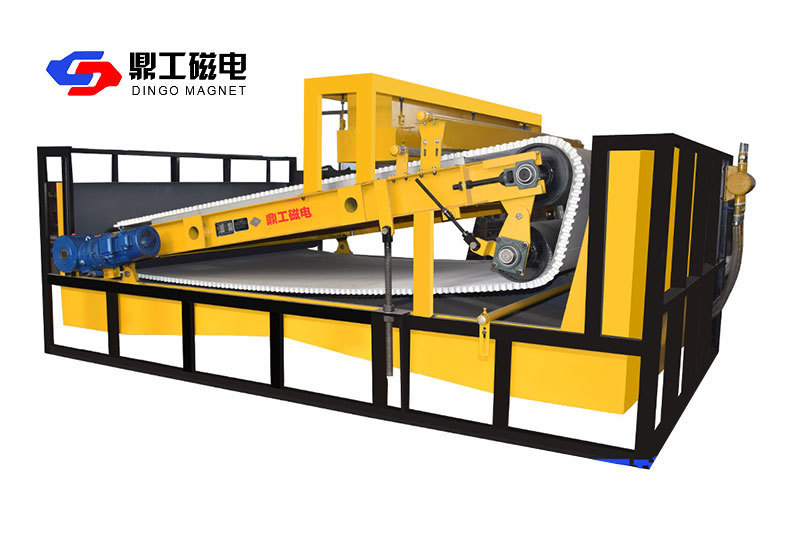

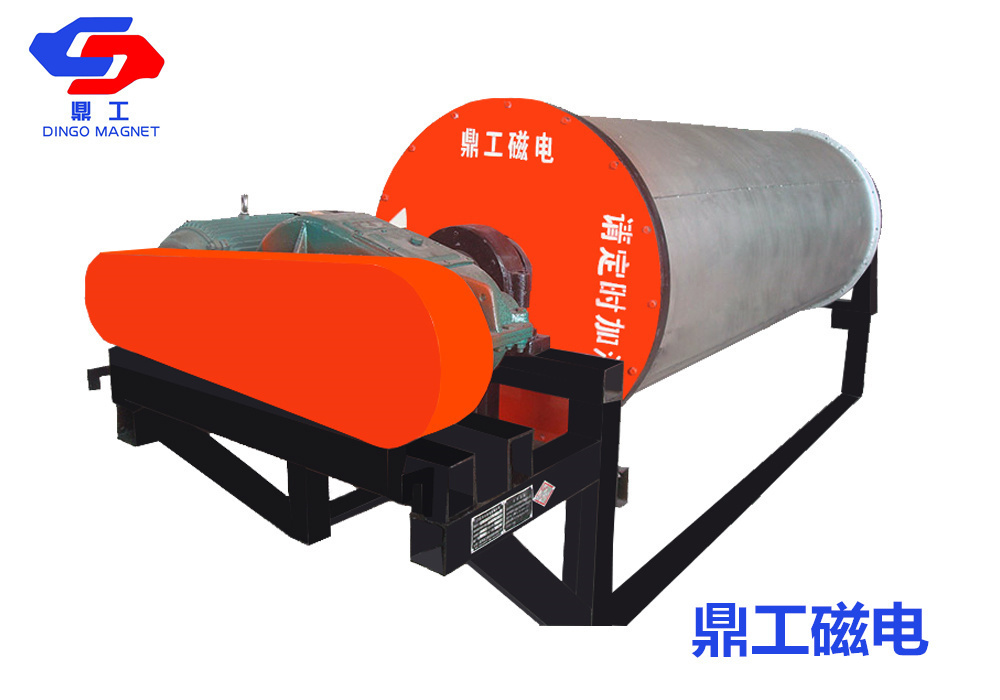

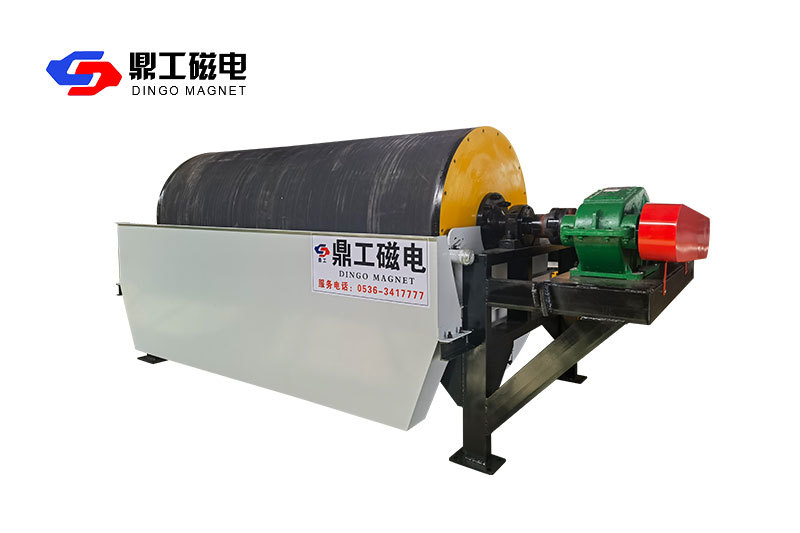

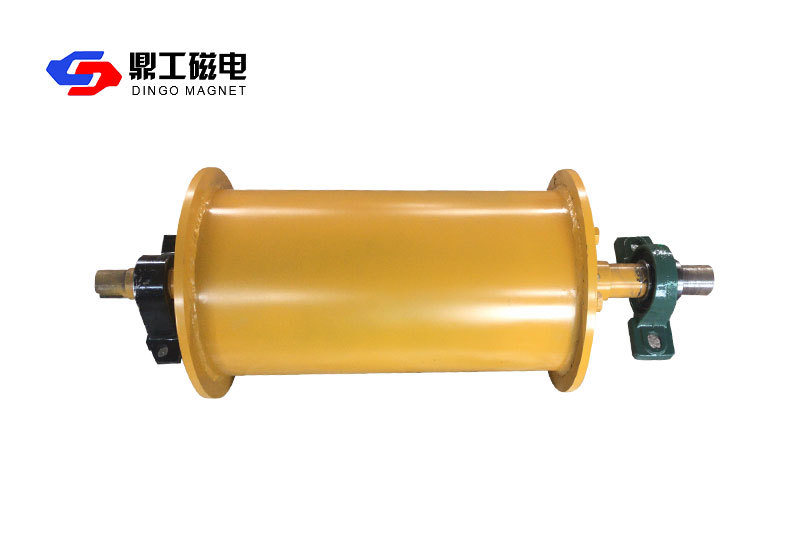

- Magnetic Pulleys: These are used in conveyor systems to remove metal contaminants from bulk materials.

- Liquid Line Traps: Perfect for liquid products, these separators ensure that any metallic particles are captured before they can contaminate the batch.

Choosing the Right Separator

When deciding which magnetic separator to use, companies should consider factors like the type of product being processed, the size of the metal contaminants, and the overall production line setup. It's not a one-size-fits-all situation, folks! Understanding these variables can lead to better safety and quality outcomes.

The Future of Magnetic Separation in the Food Industry

As technology continues to advance, so do food industry magnetic separators. Innovations like automated systems and smart sensors are making these devices more efficient. The integration of AI and machine learning could soon help in predicting contamination risks, making food production even safer. How cool is that?

Sustainability and Eco-Friendliness

Moreover, the push for sustainability in the food industry has led to the development of eco-friendly magnetic separators. These devices not only focus on metal removal but also aim to minimize waste and reduce environmental impact. It's a step in the right direction for a greener future!

Conclusion: More Than Just Metal Detectors

In conclusion, food industry magnetic separators are the unsung heroes of food safety and quality. They help protect consumers, enhance product quality, and contribute to a sustainable future. So, the next time you enjoy a meal, remember the invisible guardians working tirelessly behind the scenes to keep your food safe! Cheers to that!

food industry magnetic separators

PRODUCTS

PRODUCTS

Related Products