14

2026

-

02

The Unsung Heroes of Food Safety: Magnetic Separators

Discover how food grade magnetic separators enhance food safety and quality in the industry.

Image Source: unsplash

The Unsung Heroes of Food Safety

When it comes to ensuring our food is safe for consumption, many of us might not think of the technology working behind the scenes. Enter the world of food grade magnetic separators, a vital yet often overlooked component in the food processing industry. These devices are the unsung heroes, quietly working to keep our meals safe and sound.

What Are Food Grade Magnetic Separators?

So, what exactly are these separators? In simple terms, they are specialized tools designed to remove ferrous contaminants from food products. Think about it: metal shavings, screws, or even fragments from machinery can find their way into food during processing. Yikes! That's where food grade magnetic separators come into play.

How They Work: A Peek Under the Hood

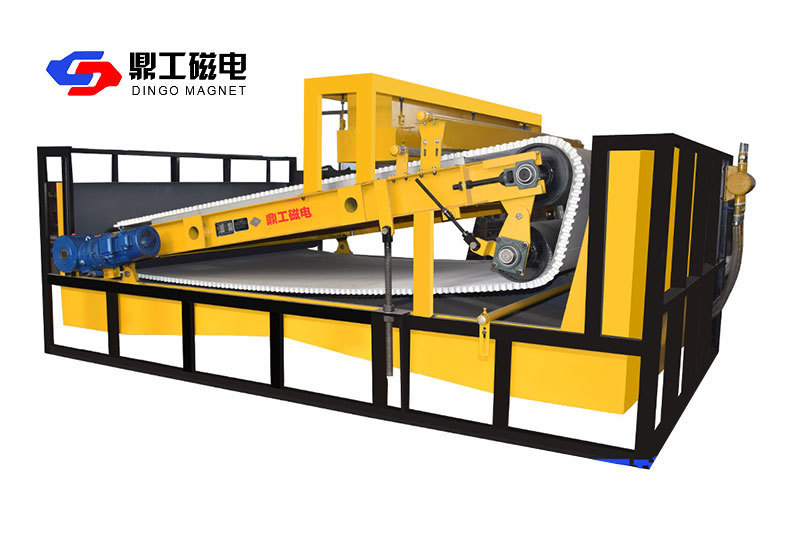

Imagine a conveyor belt, transporting a delicious stream of nuts or grains. As these products move along, a magnetic separator is strategically placed to catch any unwanted metal bits before they can cause harm. The process is quick and efficient, often using powerful magnets that attract ferrous materials while letting the food pass through unscathed. It's like having a security guard at the front gate of a banquet!

Why They're Essential

Food safety is a hot topic these days, and rightly so. With increasing consumer awareness and stringent regulations, manufacturers must prioritize quality. Using food grade magnetic separators not only helps to comply with safety standards but also builds trust with customers. After all, no one wants to bite into an apple and find a piece of metal!

Different Types of Magnetic Separators

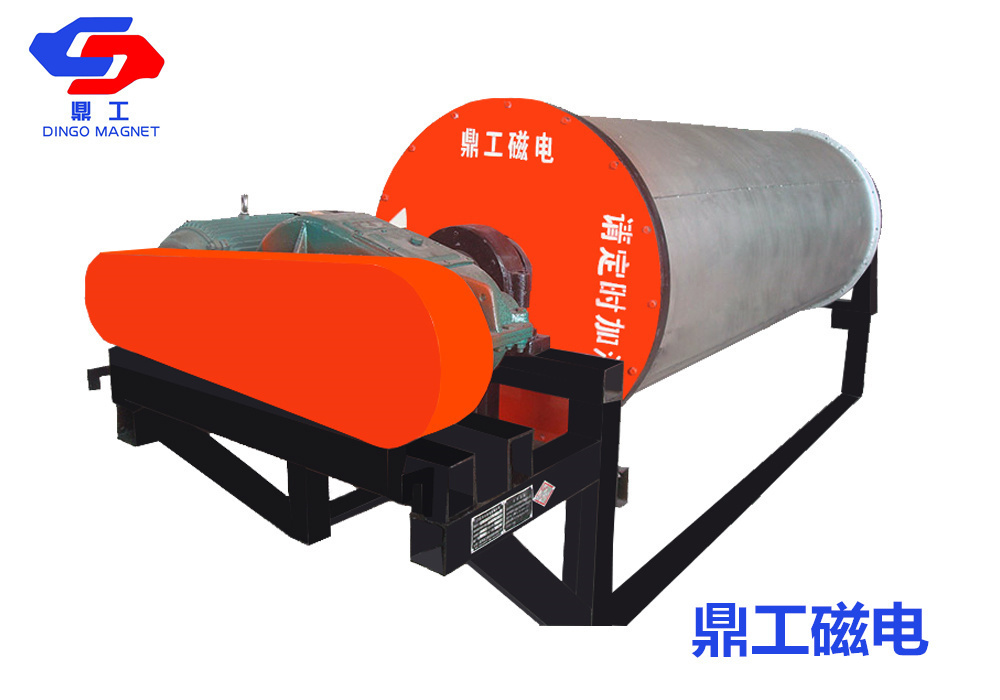

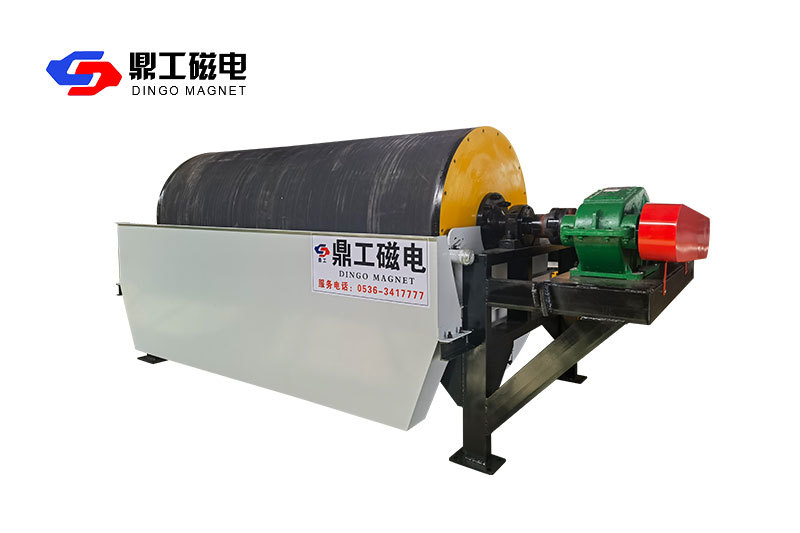

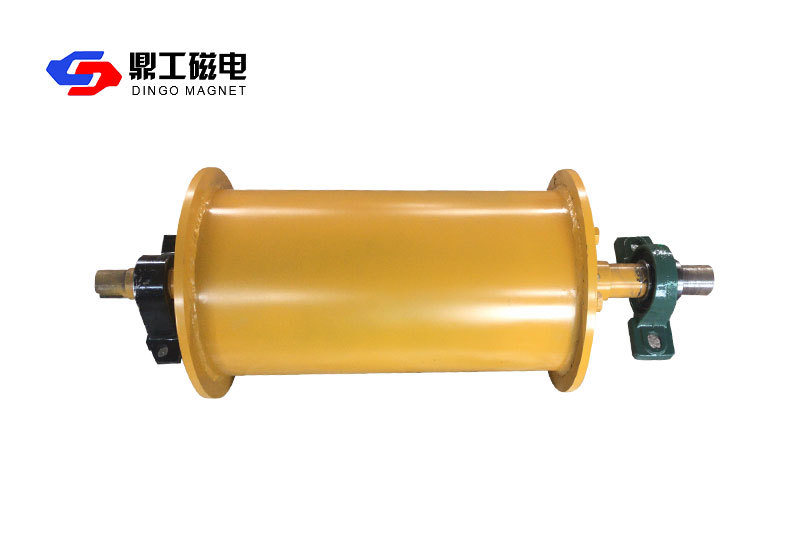

Now, let's not get ahead of ourselves! There are various types of magnetic separators, and each one serves a unique purpose. From grate magnets to liquid line separators, each design is tailored to specific needs. For instance, grate magnets are perfect for dry products, while liquid line separators are designed to work in wet processing environments. It's like choosing the right tool for the job—no one wants to use a hammer when they need a screwdriver!

Benefits Galore

Using food grade magnetic separators comes with a plethora of benefits. Firstly, they enhance product quality by ensuring that no metal contaminants make it to the consumer. Secondly, they reduce equipment wear and tear by preventing metal debris from entering machinery, which can be costly to repair. Lastly, they contribute to a safer working environment for employees. Who wouldn't want that?

Industry Applications

The applications for these magnetic separators are vast. From the dairy industry to grain processing and everything in between, they play a critical role. And it's not just about compliance; it's about creating a culture of safety and quality that resonates throughout the entire production line.

Future Trends in Food Safety

As technology evolves, so too do the methods we use to ensure food safety. The future looks promising, with innovations in magnetic separation technology leading the charge. Expect to see even more efficient designs, capable of detecting smaller ferrous particles than ever before. It's an exciting time to be in the food industry!

Conclusion

In conclusion, the role of food grade magnetic separators in the food processing industry cannot be overstated. They are crucial for maintaining safety, enhancing product quality, and ensuring compliance with regulations. So, the next time you enjoy a meal, take a moment to appreciate the technology that helps keep your food safe. Cheers to food safety!

food grade magnetic separators

PRODUCTS

PRODUCTS

Related Products