11

2026

-

02

The Unsung Hero of Food Safety: Exploring Food Processing Magnetic Separators

Discover the vital role of food processing magnetic separators in ensuring food safety and quality.

Image Source: unsplash

Introduction

When it comes to ensuring the safety of our food, there's a lot that goes on behind the scenes. One of the unsung heroes in this arena is the food processing magnetic separator. This nifty device works quietly but efficiently, keeping our meals safe and sound!

What is a Food Processing Magnetic Separator?

So, what exactly is a food processing magnetic separator? In simple terms, it's a tool designed to remove ferrous and non-ferrous metal contaminants from food products. By capturing these unwanted materials, it helps maintain product integrity and protects the end consumer from potential hazards. Talk about a game-changer!

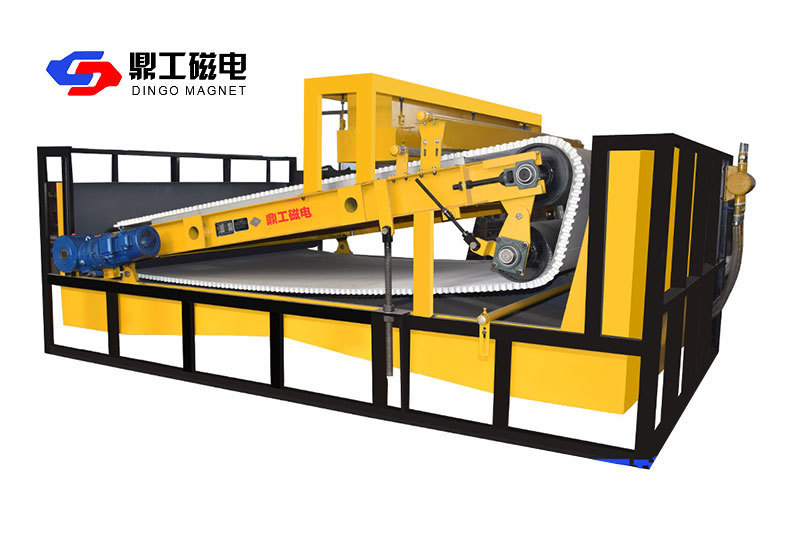

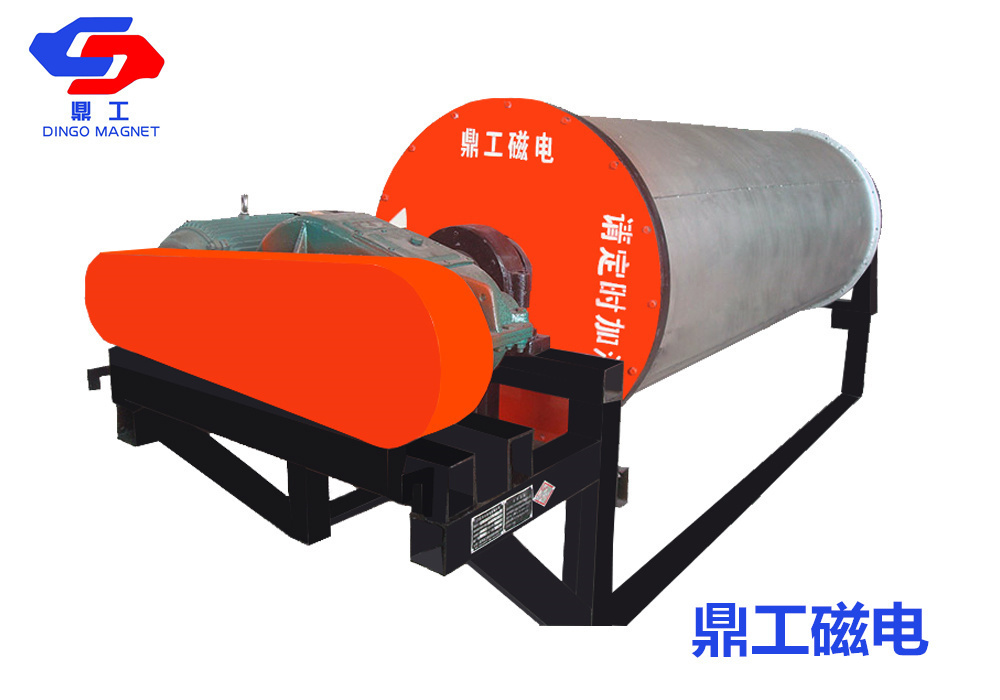

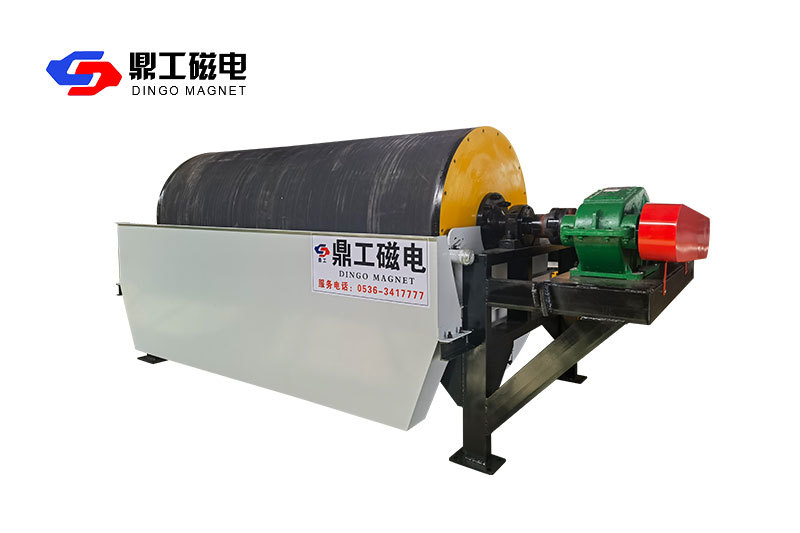

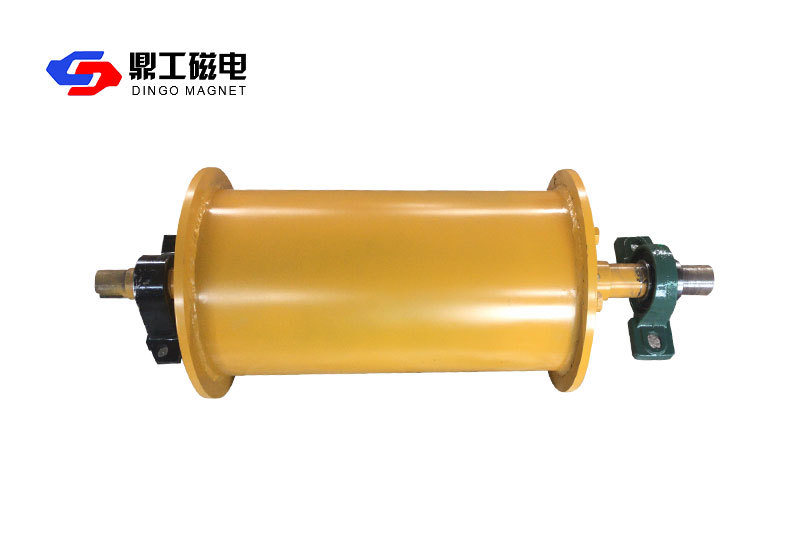

The Anatomy of the Separator

These separators typically consist of a strong magnet surrounded by a housing unit. They can be installed in various locations within a food processing line. Whether it's in bulk materials handling or finished product inspection, they make sure that no metal makes its way into our favorite snacks. Can you imagine biting into a cookie and finding metal? Yikes!

Why You Need One

In the food industry, maintaining cleanliness is paramount. The last thing any producer wants is a product recall due to contamination. Enter the food processing magnetic separator! Not only does it enhance food safety, but it also boosts consumer confidence. After all, when people know you're taking precautions, they're more likely to keep coming back for seconds!

Cost-Effectiveness

Some might say, "Why invest in a separator?" Well, let me tell you, the cost of not having one can be far greater. A single incident of contamination can lead to hefty fines, legal issues, and a tarnished reputation. Investing in a separator is like buying insurance for your business. Better safe than sorry, right?

How They Work

These separators are designed to work seamlessly with existing processes. As products flow through the machine, any metallic contaminants are drawn to the magnet and held securely, while the clean product continues its journey. It's a simple yet effective solution that keeps food processing lines running smoothly.

Types of Magnetic Separators

There are various types of these separators tailored for different applications. Some are designed for dry applications, while others work best in wet environments. Each type has its unique features, ensuring that you find the perfect fit for your needs. It's all about keeping things running like a well-oiled machine!

Installation and Maintenance

One of the best parts about these separators is their ease of installation. Many can be integrated into existing processing lines without major overhauls. Plus, they require minimal maintenance. Just regular cleaning and inspections to ensure they're in top shape. So, if you're thinking, "Can I handle this?" the answer is a resounding yes!

A Step Towards Sustainability

In today's world, sustainability is key. By using a food processing magnetic separator, you're not just protecting consumers; you're also reducing waste. By ensuring that products are free from contaminants, you're helping to cut down on the amount of food that gets tossed out due to safety concerns. Talk about a win-win!

Conclusion

In conclusion, the food processing magnetic separator might not be the star of the show, but it plays a critical role in food safety and quality assurance. With its ability to eliminate contaminants, boost consumer confidence, and support sustainability, it's definitely a device worth having in your food processing arsenal. Remember, safety first, folks!

food processing magnetic separator

PRODUCTS

PRODUCTS

Related Products