04

2026

-

02

Separation Science: The Magic of Magnetic Separators

Discover the fascinating world of magnetic separators and how they revolutionize industries.

Image Source: unsplash

Introduction to Magnetic Separators

Ever wondered how industries manage to keep their materials free from unwanted metal debris? Well, that's where magnetic separators come into play! These nifty devices are like the unsung heroes of the manufacturing world, quietly working behind the scenes to ensure efficiency and product quality.

How Do Magnetic Separators Work?

At their core, magnetic separators use the power of magnetism to attract and remove ferrous materials from a mixture. Imagine a giant magnet sweeping through a pile of metal shavings—voilà! The unwanted bits are whisked away. They're used in various sectors, from food processing to recycling, ensuring that materials are clean and safe for further processing.

Types of Magnetic Separators

There are several types of magnetic separators tailored for specific needs:

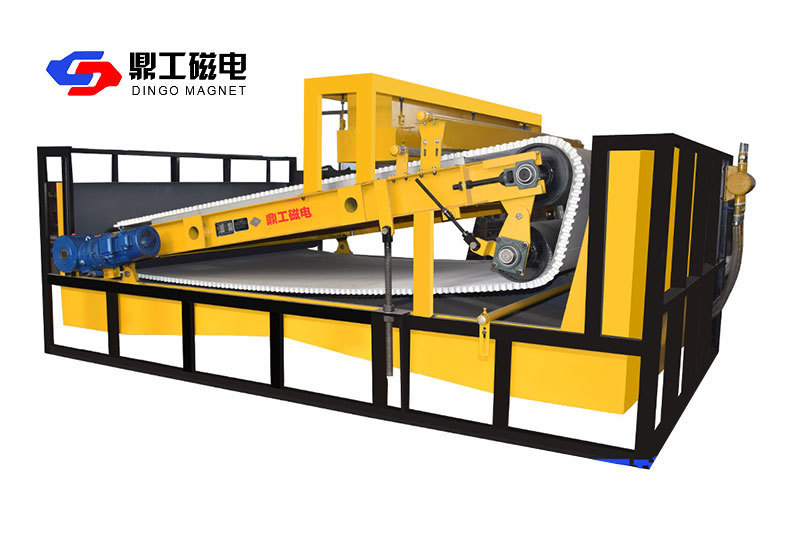

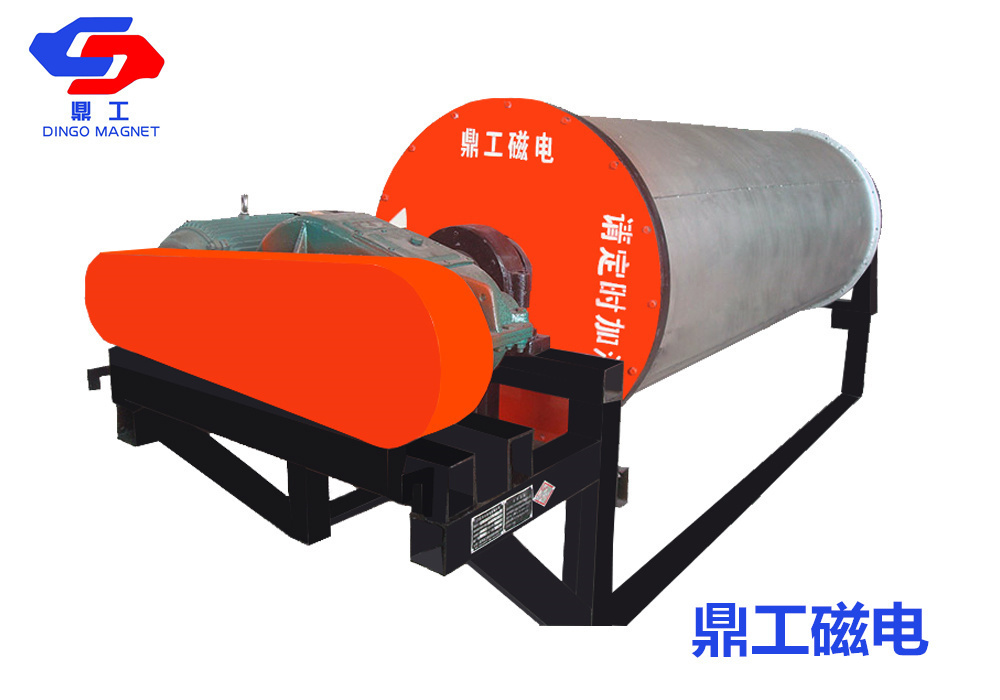

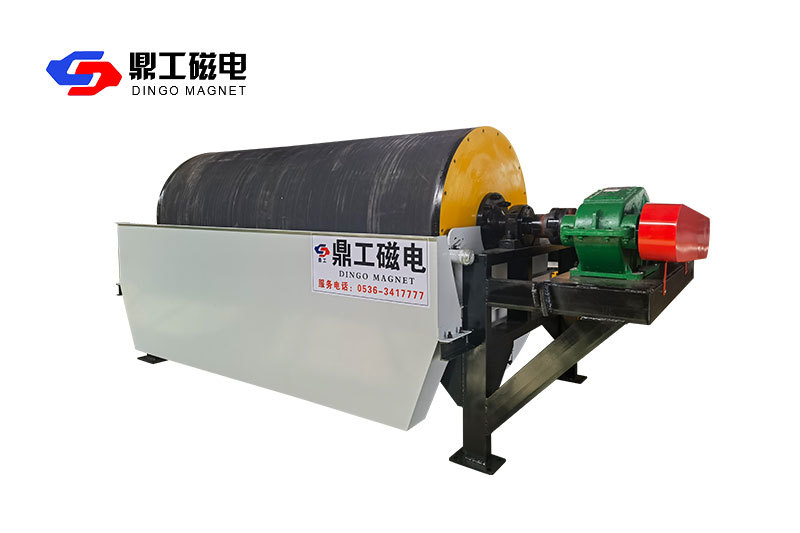

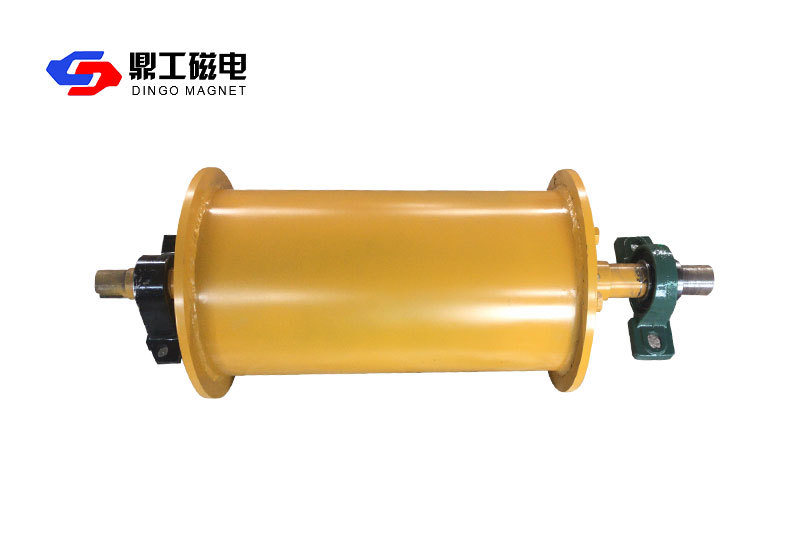

- Drum Separators: Perfect for bulk materials, these are the big guns that handle large volumes.

- Overband Separators: Ideal for conveyor systems, they catch stray metals as they pass by.

- Plate Magnets: These are installed in chutes and hoppers, providing a barrier against ferrous contaminants.

Applications of Magnetic Separators

So, where exactly do you find these devices in action? Well, let's break it down:

1. Food Industry

In the food industry, cleanliness is paramount. Magnetic separators help ensure that products are free from metal contamination, protecting both consumers and brand reputation.

2. Mining and Mineral Processing

When it comes to mining, magnetic separators are used to extract valuable minerals from ores, enhancing recovery rates and reducing waste.

3. Recycling

In recycling plants, these devices play a crucial role in sorting materials, helping to recover metals from waste streams efficiently.

The Benefits of Using Magnetic Separators

Why should industries invest in magnetic separators? Well, for starters, they significantly improve product quality and operational efficiency. Plus, they help in reducing downtime caused by equipment wear and tear due to metal contaminants. Talk about a win-win!

Choosing the Right Magnetic Separator

With so many options out there, selecting the right magnetic separator can feel like finding a needle in a haystack. It's best to consider factors like:

- The type of material being processed

- The size and shape of the contaminants

- The flow rate of the material

Consulting with experts can also help businesses make informed decisions and maximize their investment.

Future Trends in Magnetic Separation Technology

As industries evolve, so do magnetic separators. The future looks bright with advancements in technology, such as:

- Smart Magnetic Separators: Equipped with sensors for real-time monitoring and efficiency improvements.

- Eco-friendly Designs: Innovations aimed at reducing energy consumption without compromising performance.

These trends indicate a shift towards more sustainable and efficient industrial practices, which is definitely something to cheer about!

Conclusion

In conclusion, magnetic separators are invaluable assets in various industries, ensuring safety, efficiency, and quality. As technology advances, their role will only grow more critical. So, next time you see a manufacturing plant, remember the magic of magnetic separation working behind the scenes!

magnetic separators

PRODUCTS

PRODUCTS

Related Products