02

2026

-

02

The Essential Role of Magnetic Separators in Food Processing

Discover how magnetic separators enhance food safety and quality in the processing industry.

Image Source: unsplash

Understanding Magnetic Separators

So, what's the big deal about magnetic separators in food processing? Well, these nifty devices play a crucial role in ensuring the safety and quality of the food we consume. By removing metal contaminants, they help keep our meals both safe and delicious. But let's dive deeper!

How Do They Work?

Picture this: you're in a bustling food processing plant. As ingredients move along conveyor belts, magnetic separators stand guard, ready to catch any metal fragments that might sneak in. These fragments can come from various sources—broken machinery, wear and tear, or even packaging. The separators use powerful magnets to attract these unwanted particles, ensuring they don't make it into your breakfast cereal or that mid-afternoon snack.

Why Are They Important?

Here's the thing: food safety is no joke. With increasing consumer awareness and stringent regulations, the demand for safe food products has never been higher. Magnetic separators in food processing are indispensable tools in this fight. They not only protect consumers but also enhance a brand's reputation. Nobody wants to hear about a food recall due to metal contamination, right?

The Benefits

- ✔️ Quality Assurance: Magnetic separators help maintain the integrity of food products.

- ✔️ Compliance: They assist in meeting safety regulations.

- ✔️ Cost-Effective: By preventing contamination, they save companies from expensive recalls.

Types of Magnetic Separators

Not all magnetic separators are created equal! Some are designed for bulk material, while others are tailored for specific applications, like processing liquids or powders. Here's a quick rundown:

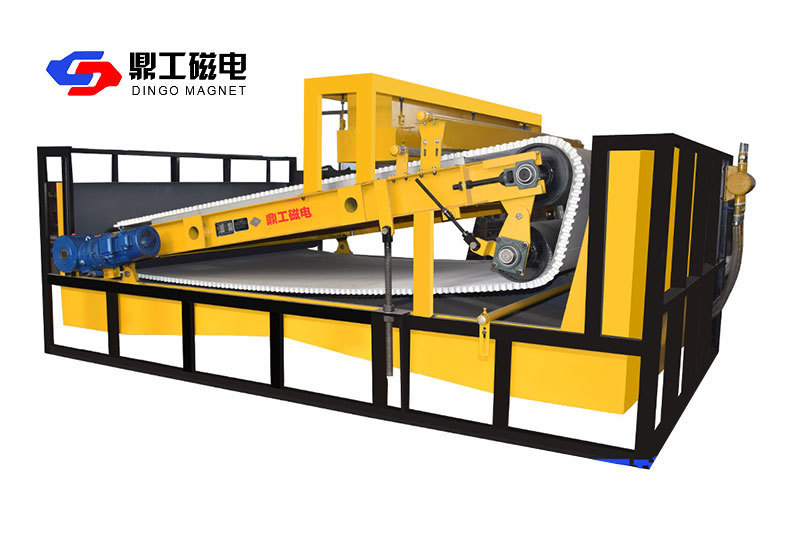

- Overband Magnets: Ideal for large conveyor systems.

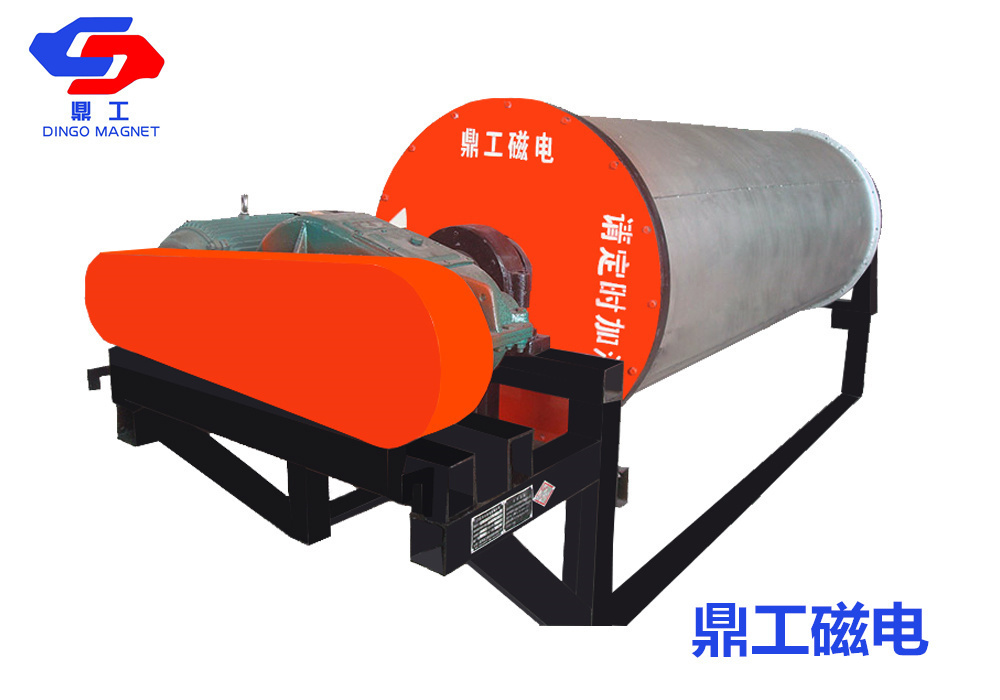

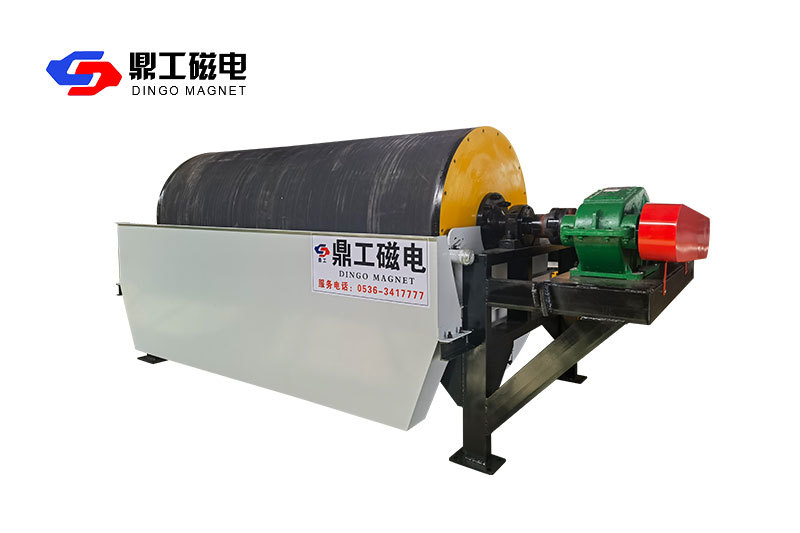

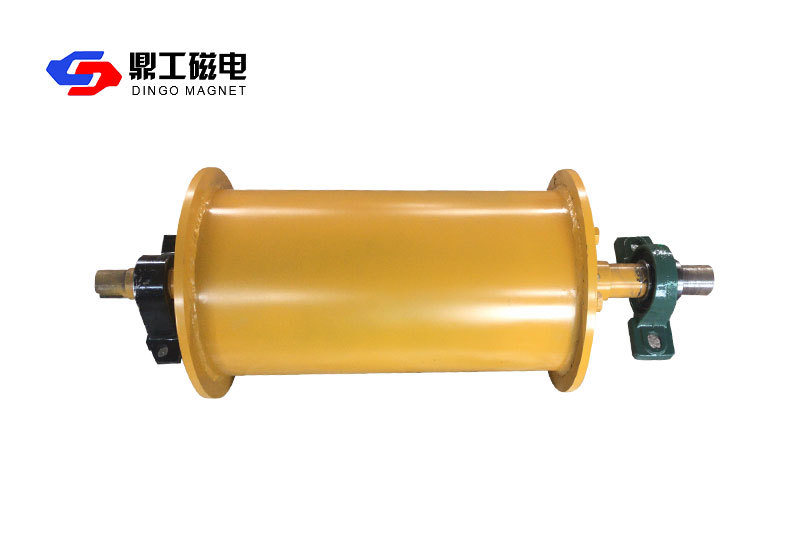

- Magnetic Drums: Perfect for continuous flow processes.

- Plate Magnets: Great for smaller operations.

Challenges and Considerations

Of course, no system is without its challenges. Magnetic separators require regular maintenance to ensure they function optimally. Moreover, businesses must choose the right type based on their specific needs. It's a bit like finding the right tool for the job—get it wrong, and you could face issues down the line.

The Future of Magnetic Separation

As technology advances, so do magnetic separators. New materials and designs are being developed to improve efficiency and effectiveness. Plus, automation is on the rise, making these systems easier to integrate into existing operations. It's an exciting time for food processing!

Conclusion

In wrapping up, magnetic separators in food processing are essential for maintaining food safety and quality. They help protect consumers, ensure compliance, and save companies from hefty costs associated with contamination. As the industry evolves, these tools will undoubtedly play a pivotal role in shaping the future of food production. So next time you enjoy a meal, take a moment to appreciate the unseen heroes working behind the scenes!

magnetic separators in food processing

PRODUCTS

PRODUCTS

Related Products