18

2025

-

12

Unlocking Efficiency: The Power of Conveyor Belt Magnetic Separators

Discover how Conveyor belt magnetic separators revolutionize industrial processes by enhancing efficiency and safety.

Introduction: The Unsung Heroes of Industry

Have you ever wondered how factories keep their production lines running smoothly? Enter the Conveyor belt magnetic separator, a game changer in the manufacturing world. These machines not only streamline processes but also play a crucial role in maintaining product integrity and safety. So, let's dive into what makes these devices so vital!

What is a Conveyor Belt Magnetic Separator?

In layman's terms, a Conveyor belt magnetic separator is a device that uses magnets to remove ferrous (iron-containing) materials from a production line. Picture this: you're at a factory where metal can accidentally mix with food products or other goods. That's where this nifty gadget comes in, ensuring that only clean, safe products make it to the end of the line.

How Does It Work?

Alright, let's break it down. The separator is installed on a conveyor belt, and as materials pass through, magnets do their magic. They attract metal debris, which is then diverted away from the main product stream. It's like having a bouncer at a club who only lets the good stuff inside!

Types of Magnetic Separators

There are a few different types of Conveyor belt magnetic separators out there:

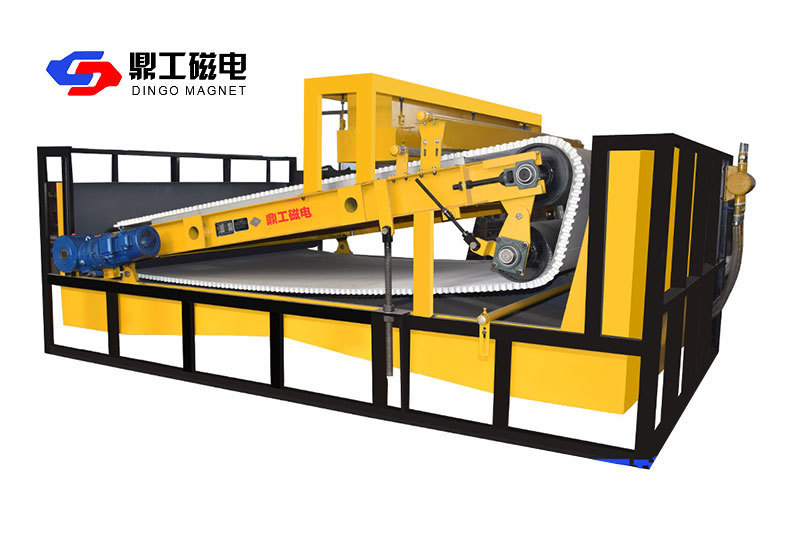

- Overband Magnetic Separators: These are positioned above the conveyor belt and are ideal for large-scale operations.

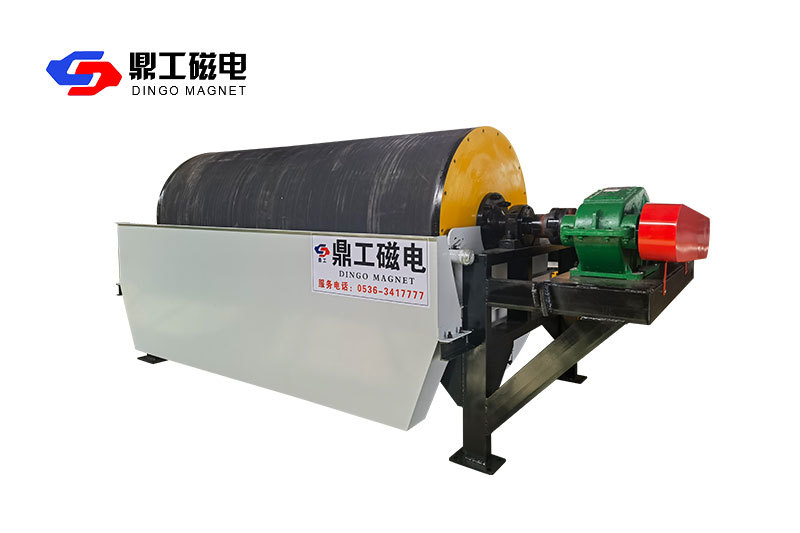

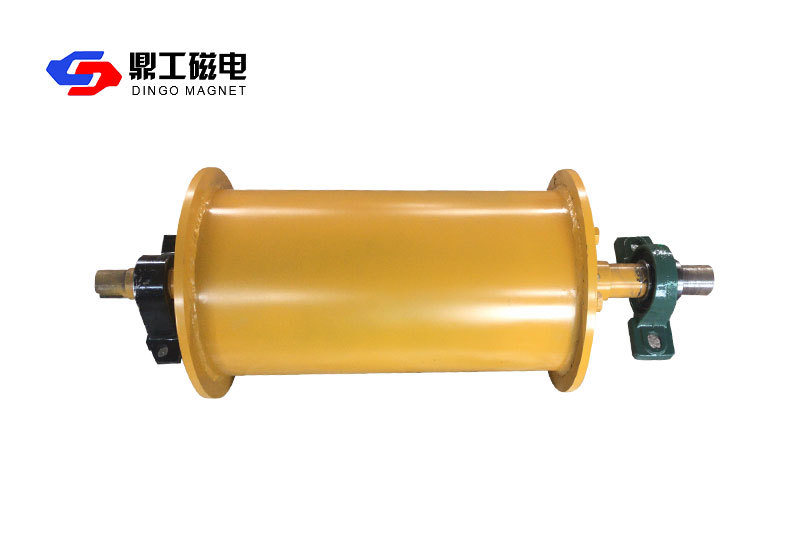

- Pulley Magnetic Separators: These replace the head pulley of a conveyor and can be very efficient in removing metal.

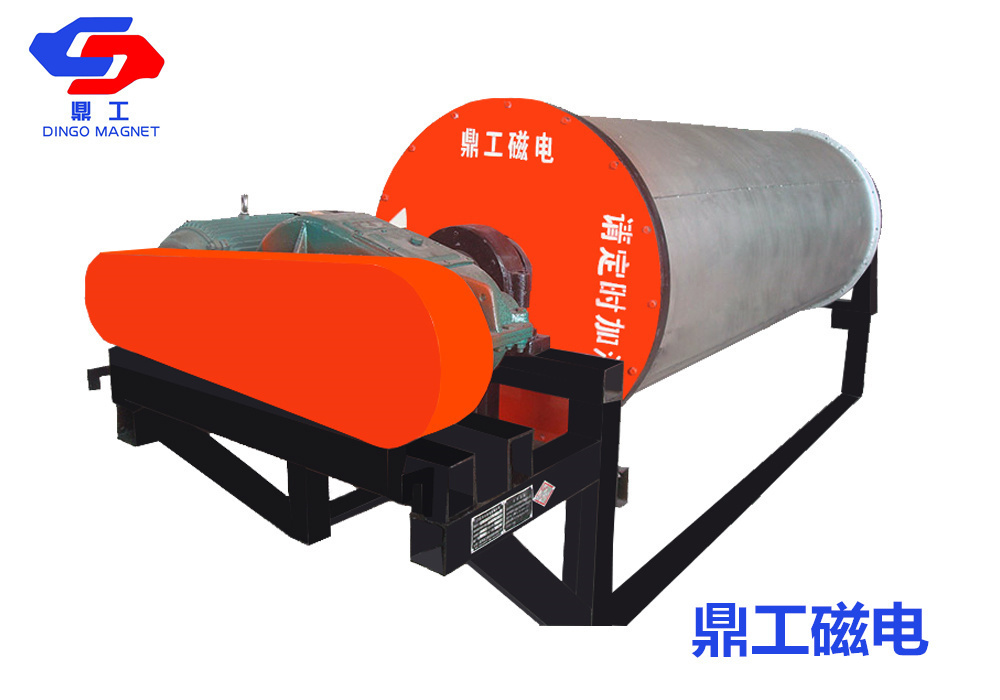

- Magnetic Drum Separators: These are cylindrical and rotate, continuously cleaning the product stream.

Why You Need One

Here's the kicker: using a Conveyor belt magnetic separator can save businesses from hefty costs associated with equipment damage and product recalls. Imagine a scenario where a small piece of metal gets into a product. Not only does it compromise safety, but it can also lead to expensive legal troubles and a tarnished reputation!

Enhancing Productivity

Moreover, these separators enhance overall productivity. With contaminants removed, products can be processed faster, and employees can focus on other vital tasks rather than manually inspecting for metal pieces. Talk about efficiency!

Applications Across Industries

From food and beverage to recycling, Conveyor belt magnetic separators find their place in diverse industries. In food processing, they ensure that no harmful metal gets into products. In recycling, they help to recover valuable metals from waste, contributing to a more sustainable future.

Case Study: A Sweet Success

Take, for instance, a candy manufacturer that was facing issues with metal contamination. After installing a Conveyor belt magnetic separator, they reported a 99% reduction in metal-related defects. Not only did they save money, but they also improved customer satisfaction. Sweet, right?

Maintenance Matters

Now, don't get too comfy! Just like any equipment, these separators need regular maintenance. Keeping them clean and checking for wear and tear will ensure they operate at peak performance. It's like giving your car a tune-up; you want to keep it running smoothly!

Conclusion: The Future is Bright

To sum it up, the Conveyor belt magnetic separator is more than just a piece of machinery; it's a cornerstone of modern manufacturing. As industries continue to evolve, these separators will play an even bigger role in ensuring safety and efficiency. So, if you haven't considered one for your operation, it might be time to hop on the bandwagon!

conveyor belt magnetic separator

PRODUCTS

PRODUCTS

Related Products