20

2025

-

11

Unlocking the Power of Magnetic Separators: A Game Changer in Industry

Explore how magnetic separators are revolutionizing industries by improving efficiency and safety.

Introduction to Magnetic Separators

Hey there! Have you ever wondered how industries maintain their efficiency while ensuring safety? Well, let me introduce you to the unsung heroes of manufacturing: magnetic separators. These nifty devices are taking the industrial world by storm, and today, we'll dive deep into their significance.

What Are Magnetic Separators?

Alright, let's break it down. Magnetic separators are tools designed to remove magnetic materials from a mixture. They work by using powerful magnets to attract ferrous materials (that's just a fancy term for metals like iron). Picture a giant magnet sweeping through a pile of debris, pulling out all the unwanted metal bits—pretty cool, right?

How Do They Work?

So, how do these bad boys actually function? Well, it's all about magnetism. When materials are fed into the separator, the magnetic field attracts ferrous particles. These particles are then collected and removed, leaving behind cleaner, safer materials for further processing. It's like having a superhero work his magic in your production line!

Why Are Magnetic Separators Important?

Now, you might be asking, "What's the big deal?" Here's the scoop: Magnetic separators enhance product purity, protect equipment from damage, and ultimately save companies a boatload of cash. Imagine if a stray metal fragment caused a machine to malfunction—yikes! Magnetic separators step in to prevent this kind of disaster.

Applications Across Industries

From food processing to recycling and mining, the applications of magnetic separators are vast. In the food industry, they ensure that no metal contaminants slip through, keeping consumers safe. In recycling, they help recover valuable metals from waste, promoting sustainability. Talk about multitasking!

Types of Magnetic Separators

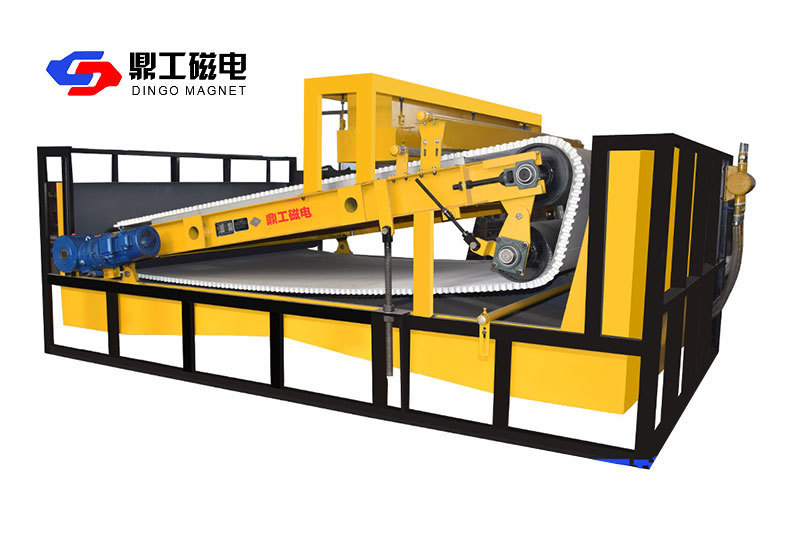

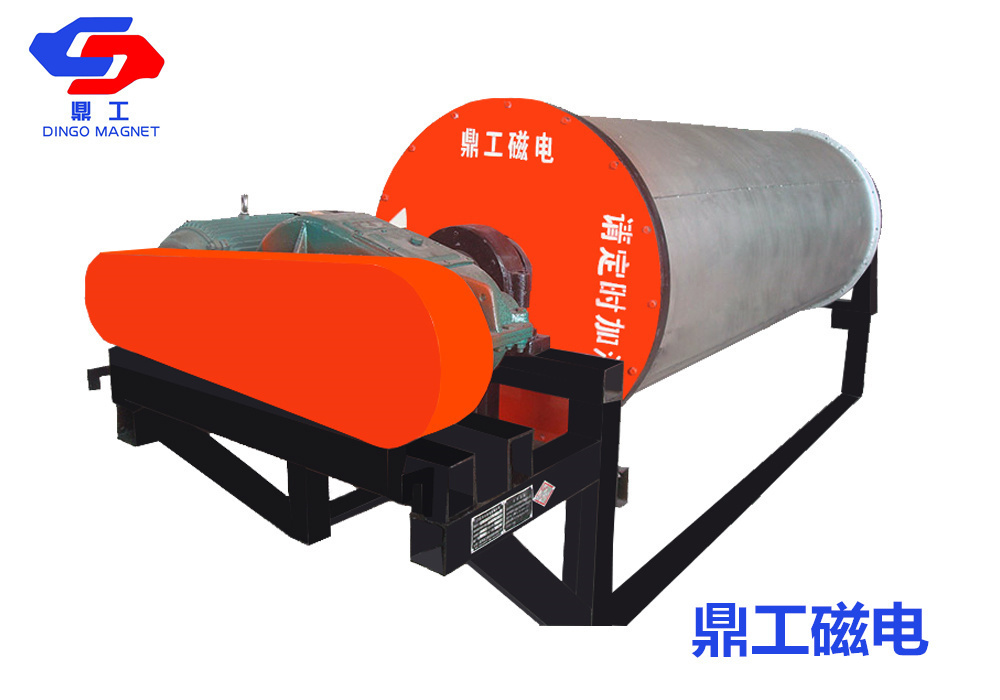

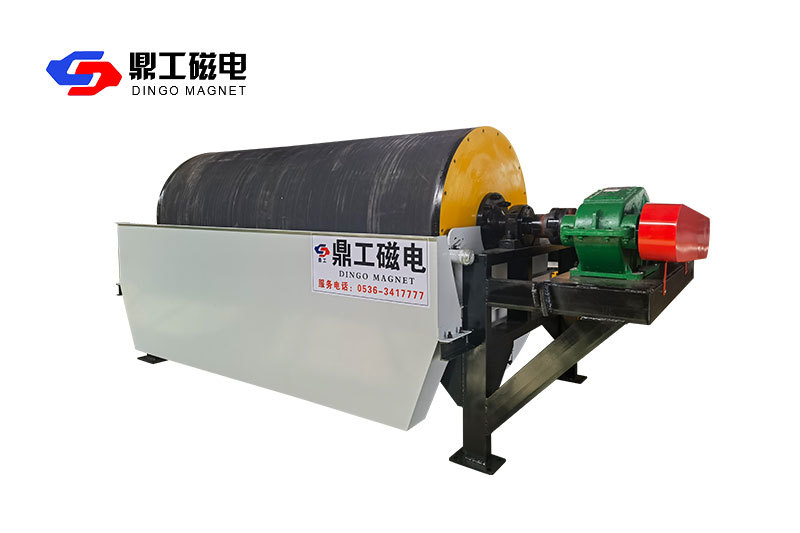

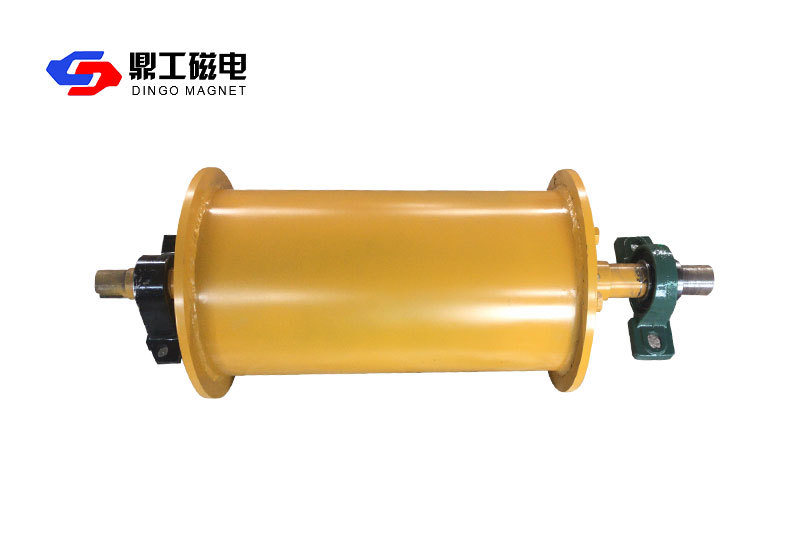

There's more than one flavor when it comes to these devices. Here's a quick rundown:

- Permanent Magnetic Separators: These bad boys use permanent magnets, making them energy-efficient and low-maintenance.

- Electromagnetic Separators: Perfect for heavy-duty applications, these separators can be turned on and off, providing flexibility.

- Magnetic Drum Separators: These are great for bulk materials, continuously removing ferrous contaminants as materials flow through.

The Future of Magnetic Separation Technology

As technology evolves, so do magnetic separators. Innovations like automated systems and advanced materials are enhancing their efficiency and effectiveness. Plus, with the growing emphasis on safety and sustainability, the demand for magnetic separators is only going to increase. It's a win-win!

Conclusion

In a nutshell, magnetic separators are more than just industrial tools; they are vital components that drive efficiency and safety in various sectors. So, the next time you hear about them, you'll know just how impactful they are in keeping industries running smoothly. Who knew magnets could be so powerful?

magnetic separators

PRODUCTS

PRODUCTS

Related Products