18

2025

-

11

The Unsung Heroes: Magnetic Separators in Food Processing

Discover how magnetic separators ensure food safety and quality in the food processing industry.

Introduction: The Hidden Guardians of Food Safety

When we munch on our favorite snacks or savor a delicious meal, we rarely ponder the lengthy journey our food has taken to reach our plates. Enter the unsung heroes of the food industry: magnetic separators in food processing. These nifty gadgets play a pivotal role in ensuring our meals are not just tasty but safe and free from contaminants.

What Are Magnetic Separators?

So, what's the deal with magnetic separators? Simply put, they're devices designed to remove ferrous materials—like iron and steel— from food products, preventing metal contamination. You wouldn't want a mouthful of metal bits with your cereal, right? These separators come in various forms, including magnetic bars, plates, and pulleys, each tailored to specific processing needs.

Why They Matter: Food Safety First!

Imagine biting into a perfectly baked loaf of bread only to discover a piece of metal! Yikes! That's where magnetic separators come into play, acting like food safety sentinels. By efficiently detecting and removing metallic contaminants, they help manufacturers comply with safety standards and regulations. In a world where food recalls are all too common, these separators can save companies from financial loss and protect consumer health.

The Types of Magnetic Separators

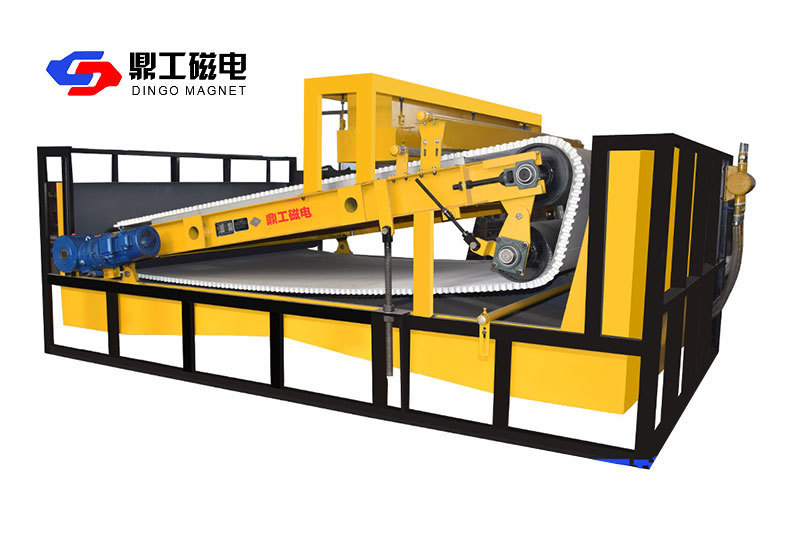

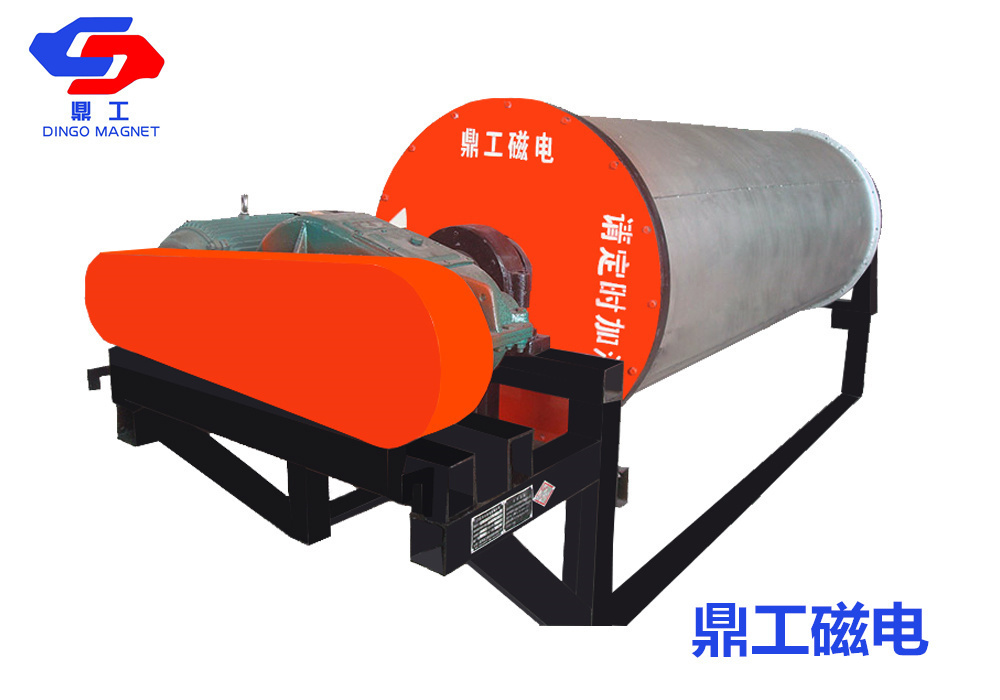

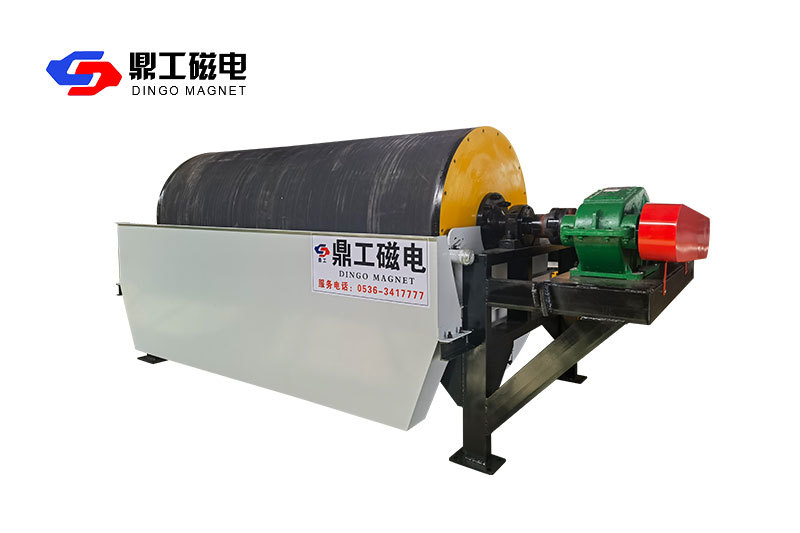

- Magnetic Grates: These are inserted into hoppers or chutes, capturing metal particles as products pass through.

- Magnetic Plates: Ideal for belt conveyors, these plates attract ferrous materials from the product stream.

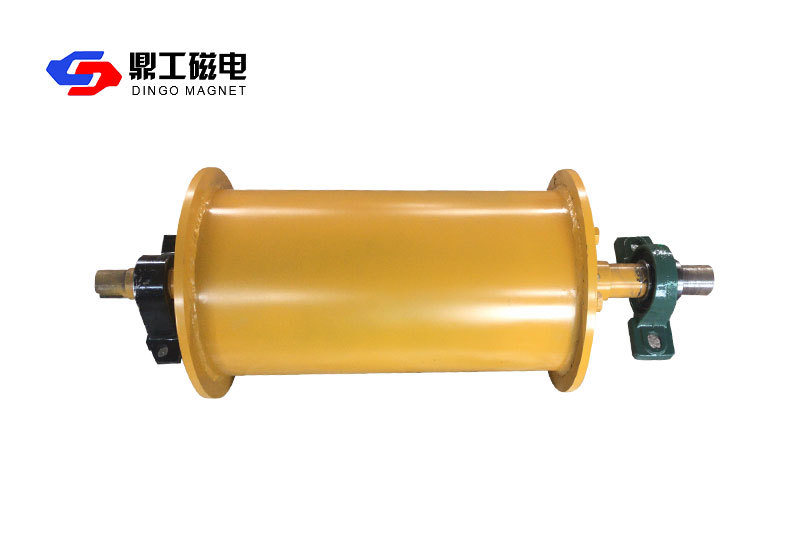

- Magnetic Pulleys: Replacing standard pulleys, these devices remove metal contaminants from conveyed materials.

Applications Across the Food Industry

Believe it or not, magnetic separators are versatile tools used in various food processing sectors. From grain milling to meat processing, they help maintain product integrity. In dairy production, for instance, they ensure that milk and cheese are free from metal shavings. As the saying goes, "An ounce of prevention is worth a pound of cure," and these separators embody that wisdom!

The Benefits of Using Magnetic Separators

Now, let's talk turkey—what are the real perks of installing these magnetic marvels? Here are a few to chew on:

- Enhanced Safety: They significantly reduce the risk of metal contamination.

- Quality Assurance: Consumers expect high-quality products, and these separators help maintain that standard.

- Cost-Effective: By preventing contamination issues, companies save on potential recalls and lawsuits.

Challenges and Considerations

Of course, like any technology, magnetic separators come with their own set of challenges. Choosing the right type and size for your processing line is crucial. Not to mention, regular maintenance is key to ensuring they function correctly. After all, nobody wants a faulty separator ruining their hard work!

Conclusion: A Must-Have for Food Processors

In a nutshell, magnetic separators in food processing are indispensable tools that help keep our food safe and delicious. By investing in these devices, food processors not only protect their products but also their reputations. So, the next time you're enjoying a meal, take a moment to appreciate the unseen efforts that go into making it safe for consumption. Who knew metal could be such a big deal?

magnetic separators in food processing

PRODUCTS

PRODUCTS

Related Products