PRODUCTS

HMDC series strong magnetic high-efficiency magnetic separator

Category:

Tel:

Email:

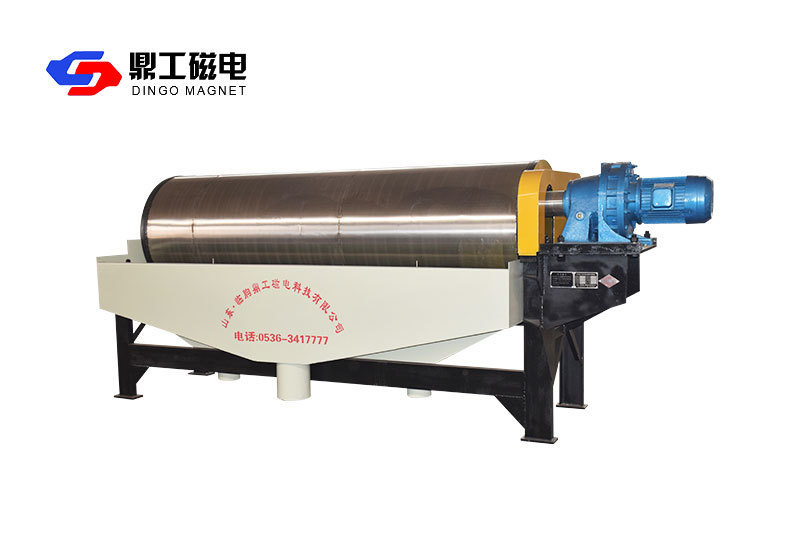

HMDC series strong magnetic high-efficiency magnetic separator

The HMDC series strong magnetic high-efficiency magnetic separator is a magnetic medium specially designed by our company for automatic and continuous recovery of heavy medium coal preparation plants, and can also be used for separating ferromagnetic ores. The adoption of advanced magnetic circuit design and new achievements in magnetic materials provides a strong guarantee for the magnetic separation effect.

Introduction to the characteristics of magnetic separators

1. The fully sealed magnetic system is composed of ferrite and rare earth neodymium iron boron composite;

2. The magnetic field has been simulated and calculated by computer, and the distribution of the magnetic field is reasonable, without demagnetization after long-term use;

3. The tank body adopts a computer simulated fluid design to effectively prevent slurry sedimentation and blockage;

4. The addition of aluminum oxide wear-resistant ceramic sheets on the outer surface of the stainless steel cylinder and inside the tank body of the magnetic separator will increase the service life of the cylinder and tank body by more than double;

5. The magnetic system adjustment is convenient and reliable, with no magnetic leakage to the main shaft and stable bearing operation;

6. Cleverly designed the corresponding structure in the sorting equipment to generate reasonable slurry flow direction;

7. The dual drum magnetic separator adopts a modular structure to facilitate magnetic separation operations and transportation installation;

8. Strong adaptability to changes in parameters such as double material flow rate and concentration;

9. Selection particle size range: 0-3mm;

10. Simple structure, large processing capacity, convenient operation, and easy maintenance.

Working principle

The HMDC series strong magnetic high-efficiency magnetic separator utilizes the magnetic force generated by the permanent magnet system to attract magnetic minerals from the slurry to the surface of the cylinder, and rotates with the cylinder. After being separated from the magnetic field, it is discharged from the machine under the action of gravity and scraper, instead of magnetic materials being discharged from the tailings port to complete the recycling operation.

Product parameters

| Model specifications | Drum diameter mm | Drum length Lmm | Amm | Bmm | Cmm | Dmm | Emm | Hmm | H1mm | Motor power kw | Weight kg |

| HMDC-918 | 914(36) | 1834(72) | 3050 | 2038 | 1827 | 870 | 845 | 1605 | 1118 | 4.0 | 2360 |

| HMDC-921 | 914(36) | 2138(84) | 3355 | 2342 | 1827 | 870 | 845 | 1605 | 1118 | 4.0 | 2650 |

| HMDC-924 | 914(36) | 2442(86) | 3660 | 2650 | 1827 | 870 | 845 | 1605 | 1118 | 4.0 | 2830 |

| HMDC-927 | 914(36) | 2746(108) | 3995 | 2954 | 1827 | 870 | 845 | 1605 | 1118 | 5.5 | 3260 |

| HMDC-930 | 914(36) | 2980(117) | 4220 | 3258 | 1827 | 870 | 845 | 1605 | 1118 | 5.5 | 3350 |

| HMDC-1221 | 1219(48) | 2138(84) | 3475 | 2342 | 2150 | 1175 | 1150 | 1910 | 1423 | 5.5 | 3180 |

| HMDC-1224 | 1219(48) | 2442(86) | 3910 | 2650 | 2150 | 1175 | 1150 | 1910 | 1423 | 5.5 | 3530 |

| HMDC-1230 | 1219(48) | 2980(117) | 4470 | 3258 | 2150 | 1175 | 1150 | 1910 | 1423 | 7.5 | 4100 |

Related Products